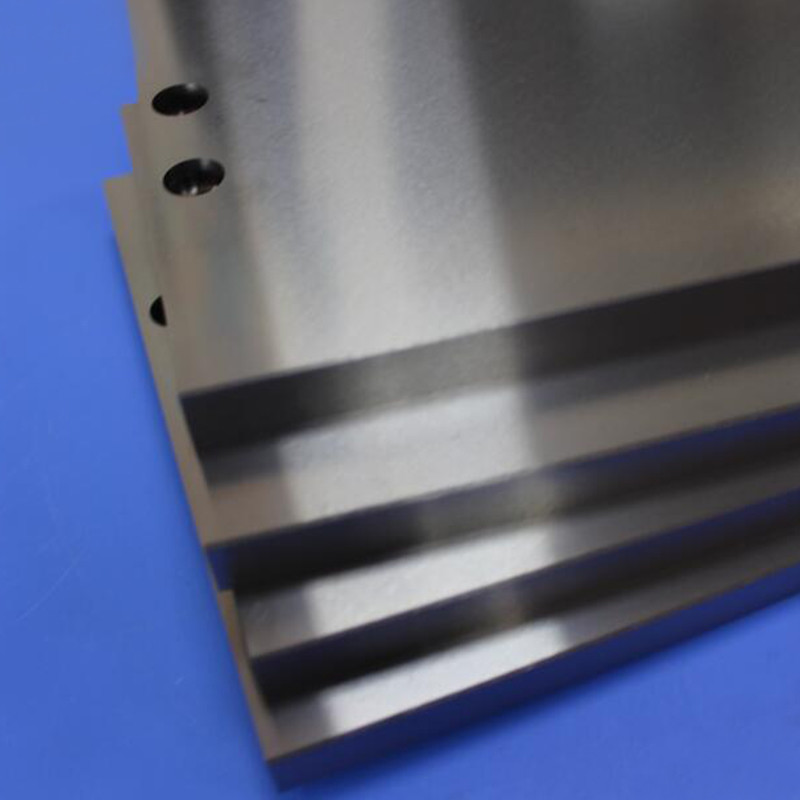

Tungsten Steel Sheet 3D Glass Hot Bending Tungsten Carbide Mold Sheet

Tungsten steel sheet dimension: 200x125x10mm with 6 holes.

This 3D glass hot-bending tungsten steel mold sheet, also known as a soaking plate, serves as a high-temperature pressing material used in glass hot bending machines. We specialize in producing tungsten steel mold materials for 3D mobile phone glass screens and glass lens hot bending pressing operations.

Manufacturing Process & Applications

The critical production process for mobile phone 3D glass screens and lenses involves hot bending forming. During high-temperature hot pressing in bending machines, specialized powder metallurgy soaking plates are essential for operations at temperatures reaching 950°C to 1150°C or higher. These extreme conditions demand materials with exceptional high-temperature resistance, thermal conductivity, and corrosion resistance without deformation.

Glass materials exhibit strong corrosive effects under high temperatures, requiring soaking plates with superior compactness, high hardness, thermal stability, and oxidation resistance. This represents a significant challenge for powder metallurgy technology, which involves forming and sintering metal powders to create specialized materials.

Custom Specifications & Production Requirements

We customize 3D hot bending glass tungsten steel mold soaking plates according to specific customer requirements. Mobile 3D glass production demands powder metallurgy materials capable of withstanding long-term hot-pressing conditions with excellent temperature and corrosion resistance.

Standard operations typically require three upper and three lower heat plates, meaning each equipment set needs six specially processed hot-rolled glass tungsten steel molds. Key quality requirements include durable lifespan, high-temperature resistance, thermal conductivity, and corrosion resistance for mass production applications.

Technical Parameters

3D Glass Characteristics:

- Light, thin, transparent, and clean

- Anti-fingerprint and anti-glare properties

- Hard, scratch-resistant, and weather-resistant

- Capable of creating 3D multi-shape appearances

- Enhanced arc shapes and edge touch functionality

- Superior touch feel and grip experience

Advancements in communication technologies including 4G, 5G, and wireless charging have accelerated 3D glass adoption in mobile phones, creating increased demand for high-temperature resistant powder metallurgy materials.

Product Advantages

| Feature |

Description |

| Outstanding Wear Resistance |

Tungsten carbide embedded material provides exceptional hardness and wear resistance, capable of withstanding friction and impact from high-speed pump operation. |

| Superior Corrosion Resistance |

The embedded structure effectively isolates external media from corroding the steel, extending product lifespan and suitability for various liquid environments. |

| Excellent Sealing Performance |

Dynamic and static ring component design ensures reliable sealing during pump operation, minimizing leakage risks. |

| Suitable for High-Pressure Environments |

Tungsten steel inserts withstand high-pressure working conditions in water pumps, ensuring system stability. |

Leveraging 60 years of cemented carbide military technology and Zhuzhou's complete industrial chain, we collaborate with leading powder metallurgy institutes including Central South University to provide high-quality powder metallurgy materials, specifically for mobile 3D glass hot bending production applications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!