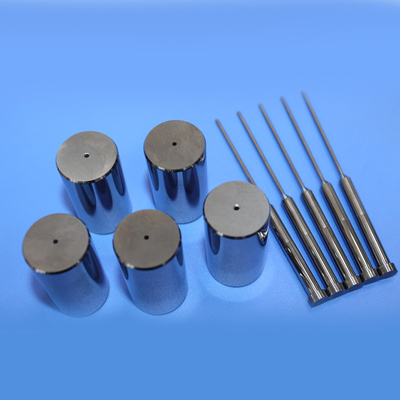

Superior Wear Resistance Cemented Carbide Plunger and Piston Cylinder

Carbide piston cylinder and plunger, also referred to as cylinder and shaft assemblies, are engineered for applications requiring sliding fits and running fits with minimal clearances for precise shaft guidance. These components maintain virtually no noticeable clearance after assembly, ensuring optimal performance in demanding industrial applications.

In mechanical engineering, fit refers to the clearance between two mating parts—specifically tungsten carbide cylinders and plungers. The selection of engineering fit determines whether components can move relative to each other (clearance fit) or function as an integrated unit (tight interference fit).

Our tungsten carbide processing expertise focuses on regulating high tolerances between mating shafts and cylinders to deliver superior performance characteristics.

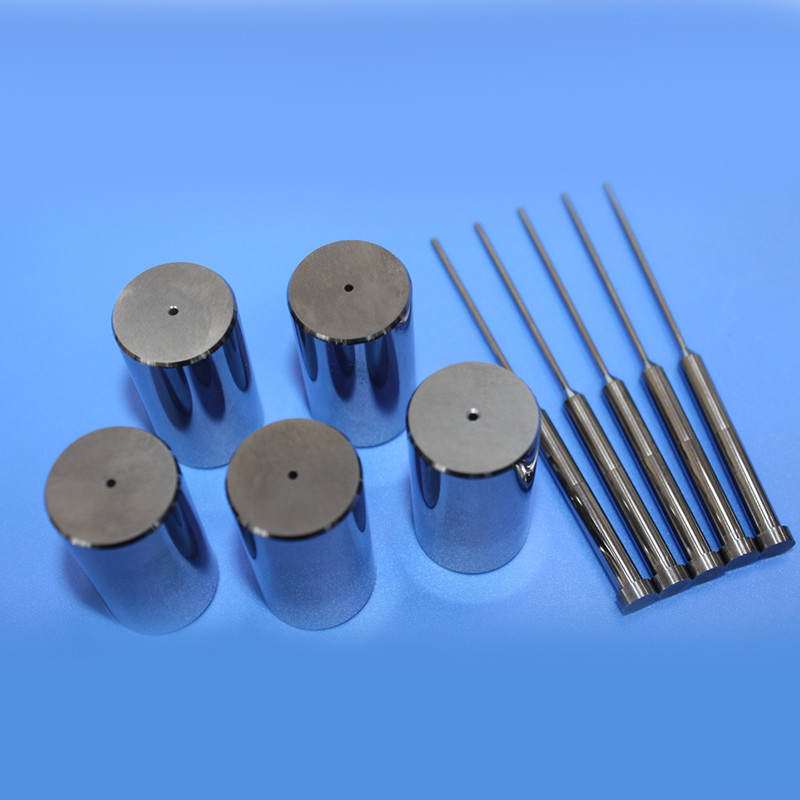

Technical Specifications

Available technical literature indicates the following specifications:

• Geometric tolerance requirements: All tungsten steel precision parts within ±0.002

• No conflict between feature linear and geometric tolerances: 0.001-0.002

Product Drawings

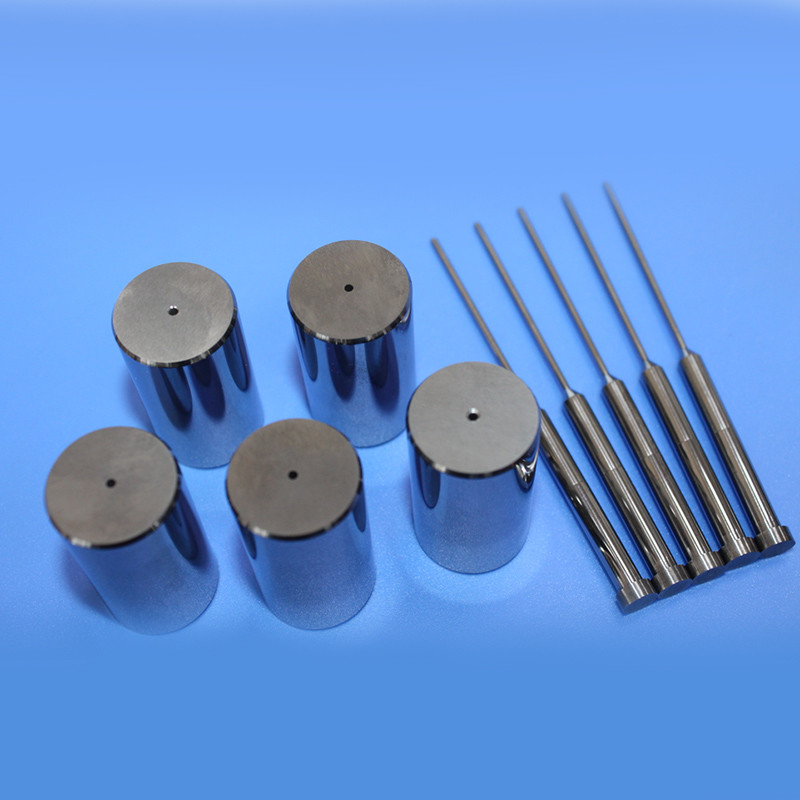

Our Manufacturing Advantages

Our company specializes in manufacturing hard alloy insert pins for precision mold applications where exceptional accuracy is paramount. Product consistency serves as the primary standard for this product line.

Tungsten carbide plungers used in electronic ceramic precision molds require mass production while maintaining excellent consistency across every shaft. This demands strict control throughout each finishing process stage.

We manufacture hard alloy insert pins according to precision mold manufacturer specifications, guaranteeing product consistency with tolerance requirements of +0.002mm. The surface finish requirement for carbide cylinders and plungers is 0.2, meeting the highest standards for mechanical piston applications.

| 1 |

National high-tech enterprise certification |

| 2 |

Processing high tolerance accuracy ±0.001mm |

| 3 |

Wear-resistant, heat-resistant, and anti-corrosion properties |

Technical Support & Services

We provide comprehensive technical support and services for our tungsten carbide processing products. Our technical specialists assist with product selection, installation, and operational guidance. We also offer on-site technical support, troubleshooting, and maintenance services.

Our training curriculum includes courses ranging from basic product overviews to advanced topics covering troubleshooting, maintenance, and installation procedures.

Customer satisfaction remains our top priority. Our team is committed to delivering premium quality products and services while building lasting, trusted relationships with our clients.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!