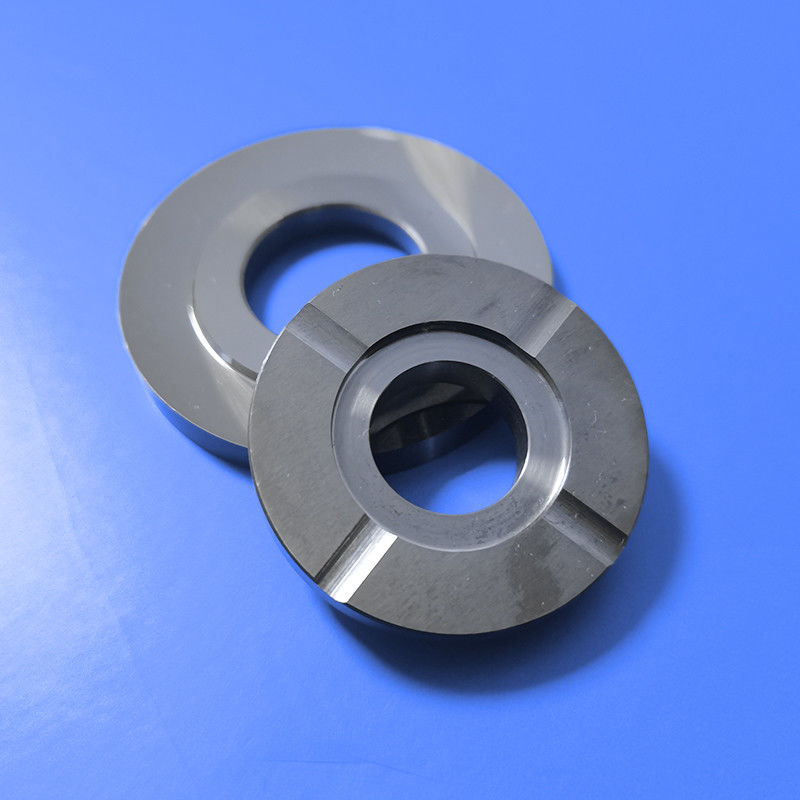

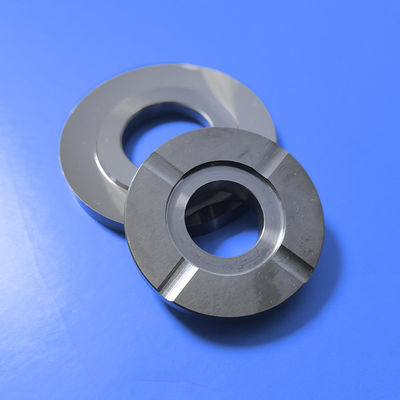

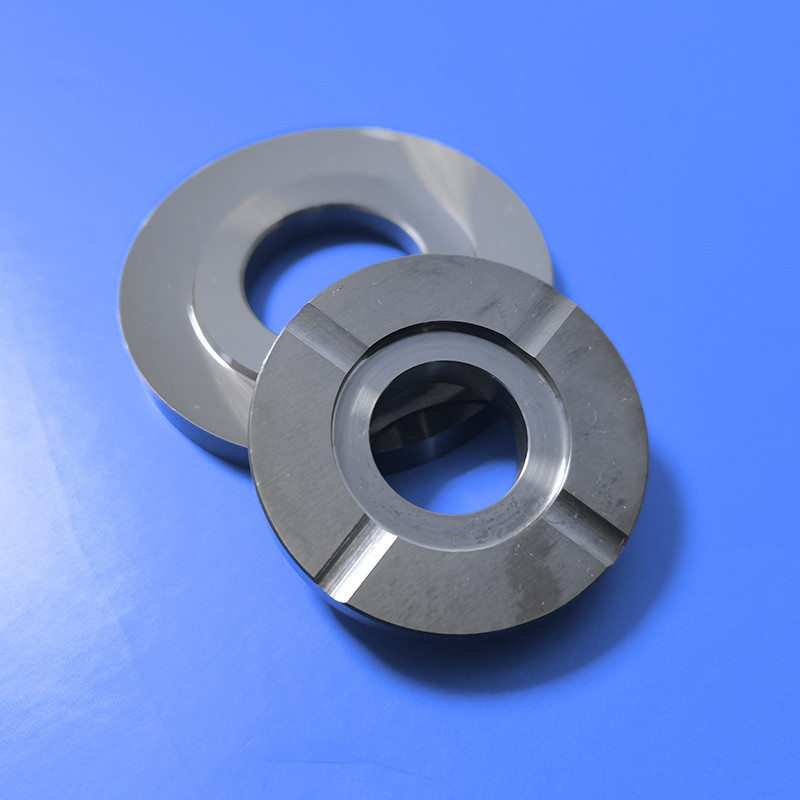

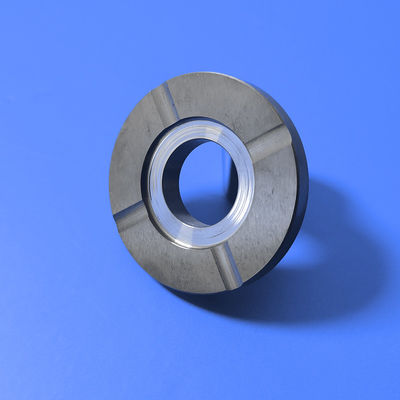

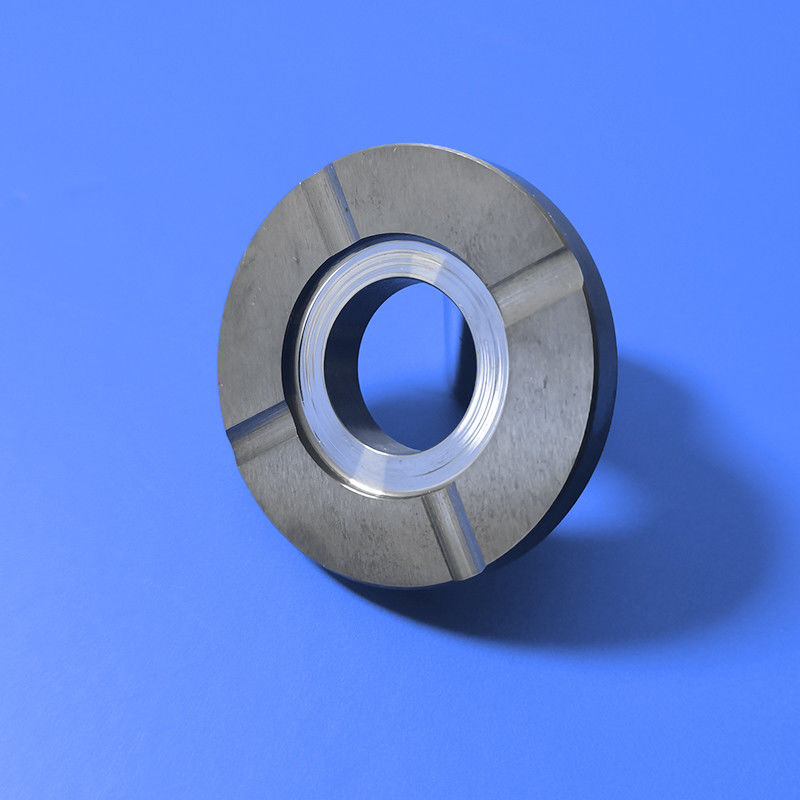

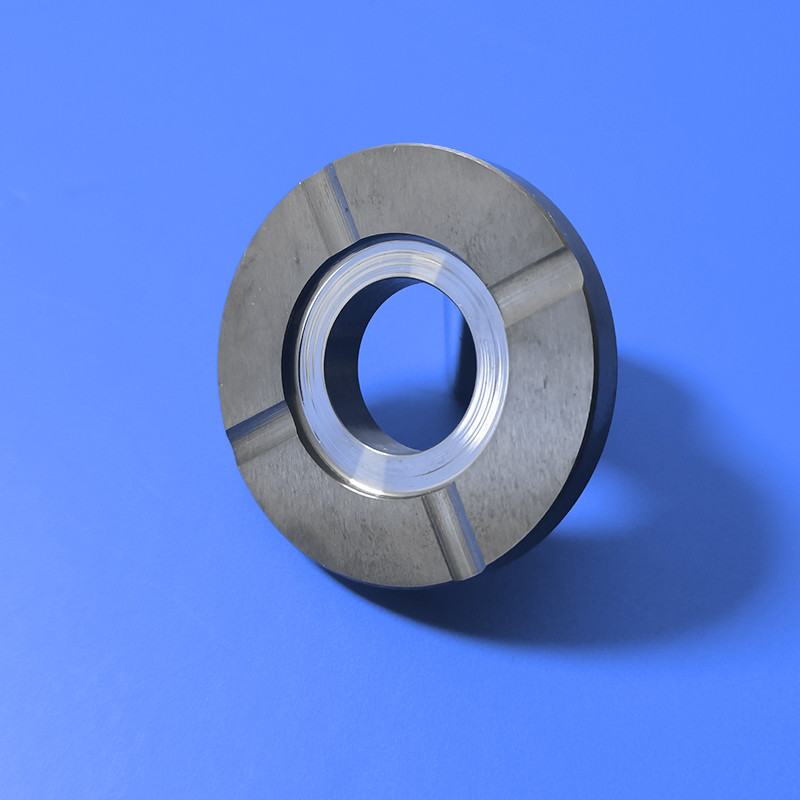

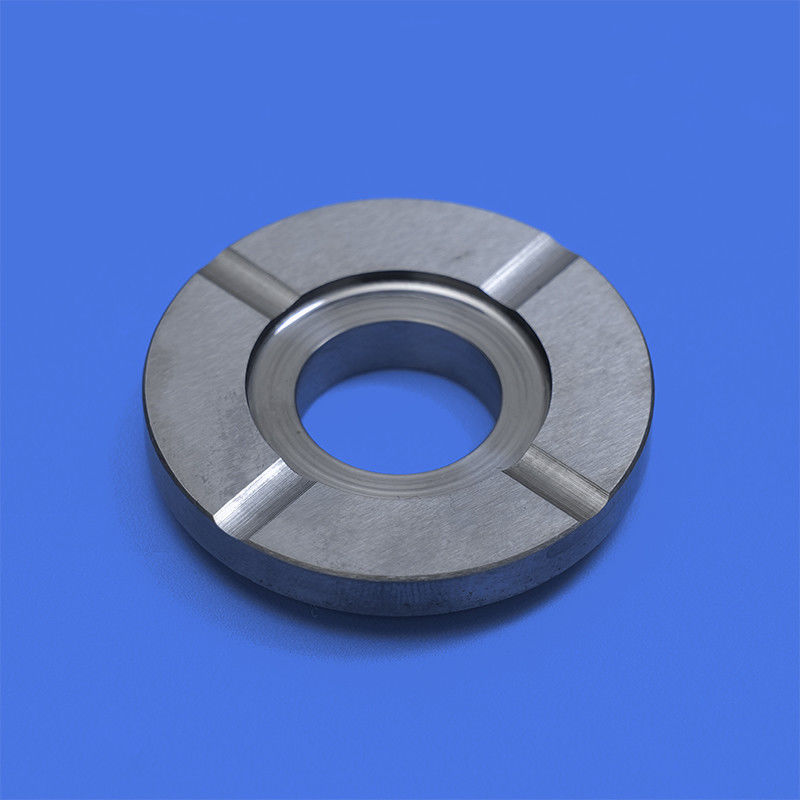

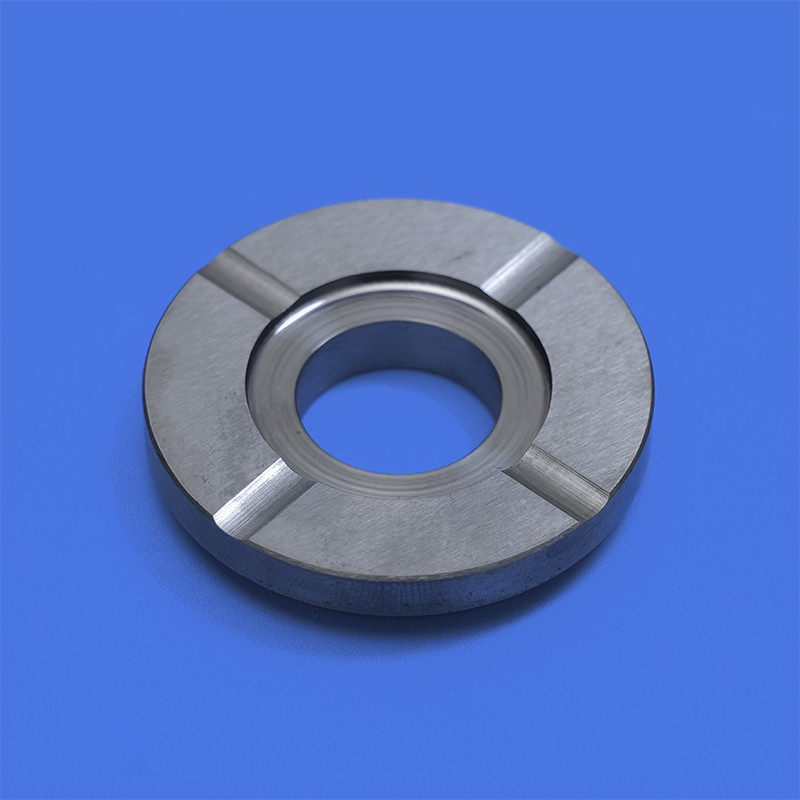

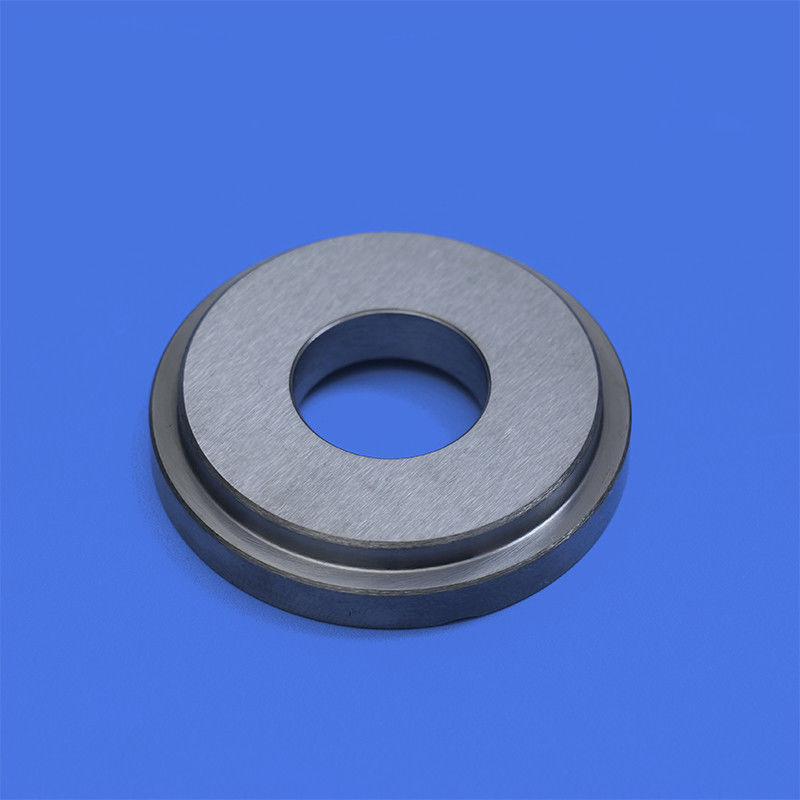

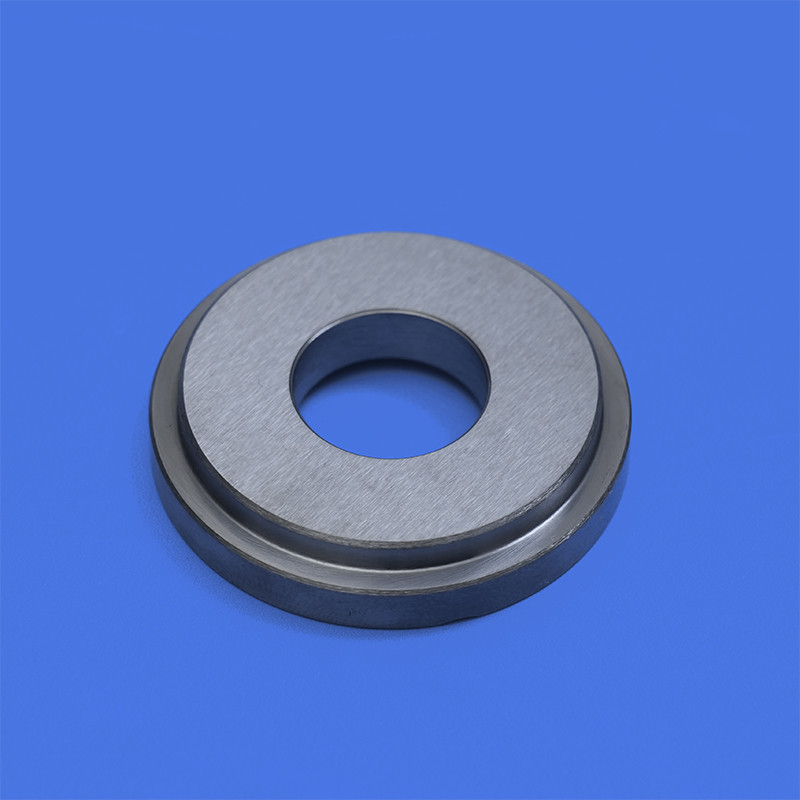

Tungsten Carbide Bearing Rings for Oilfield Machinery

Tungsten carbide bearing rings present significant manufacturing challenges due to their precision requirements. Both surfaces and the inner table undergo extensive grinding and polishing processes, with the inner table flatness maintained within 0.005 tolerance.

These heavy equipment components are extensively utilized in liquid drilling applications within the oil and gas industry. The demanding operational environments—including sand-laden wells, heavy oil wells, and high-pressure anti-oleophobic wells—contain water, various gases, wax, sand, and highly corrosive substances. Oil pumps must extract oil and natural gas from formations hundreds to thousands of meters deep, necessitating valve bushings, valve cores, valve balls, and valve seats with exceptional sealing capabilities, wear resistance, and corrosion resistance. In deep oil wells with high water content, strong corrosiveness, and significant sand content, tungsten carbide valve bushings demonstrate superior performance through their high density, exceptional wear resistance, and corrosion-resistant properties.

Product Specifications

| Model Number |

SX0984 |

| Application |

Oil & Gas Industry |

| Features |

Abrasion Resistant |

| Strength |

Flexural Strength & Bending Strength |

| Surface Finish |

Smooth, Shiny |

| Structure |

with Grooves |

| Transport Package |

Safety Packaging |

| Specification |

Customized |

| Origin |

China |

| Production Capacity |

10000 PCS/Month |

Petroleum Industry Applications

Tungsten carbide hard alloy serves critical functions across petroleum exploration, extraction, drilling, and production operations:

- Drill Bits and Cutting Tools: Widely employed in rock drill bits and three-cone bits for geological exploration and underground drilling, leveraging exceptional hardness and wear resistance

- Oil Well Components: Essential for manufacturing pump parts, valves, and seals requiring high wear resistance, corrosion resistance, and high-temperature performance

- Pipeline Cutting Tools: Utilized in maintenance and repair operations for cutting and repairing petroleum pipelines

- Oil Extraction Tools: Applied in lifting pumps and submersible pump components that must withstand high loads and harsh environmental conditions

- Petroleum Pipeline Repair Tools: Manufactured for durable and effective pipeline maintenance equipment

- Geological Exploration Tools: Commonly used in core drill bits and drilling equipment for obtaining underground rock samples

Manufacturing Excellence

Zhuzhou Sanxin Cemented Carbide Manufacturing Co., Ltd specializes in cemented carbide raw material research and development, processing, sales, and aftermarket services. With a dedicated technical team and specialized OEM capabilities, Sanxin delivers high-quality tungsten carbide products and improvement solutions.

Established: 2003

Factory Expansion: Two main factories built in 2007

Quality Certification: ISO 9001:2015 (2017)

Enterprise Status: National High-tech Enterprise (2017)

International Trade: Foreign trading license obtained (2017)

Industry Recognition: Confirmed as CLEP supplier (2021)

Innovation Portfolio: 20+ patent certificates

Operating under the principles of "quality and customer first," "samples available," "punctual delivery," "mutual benefit," "focus on innovation," and "service creates value," Sanxin consistently delivers exceptional carbide value to the market.

Quality Assurance & Technical Capabilities

- National high-tech enterprise certification

- Processing high tolerance accuracy ±0.001mm

- Superior wear-resistant, heat-resistant, and anti-corrosion properties

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!