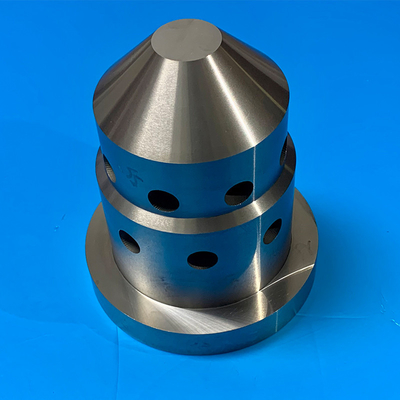

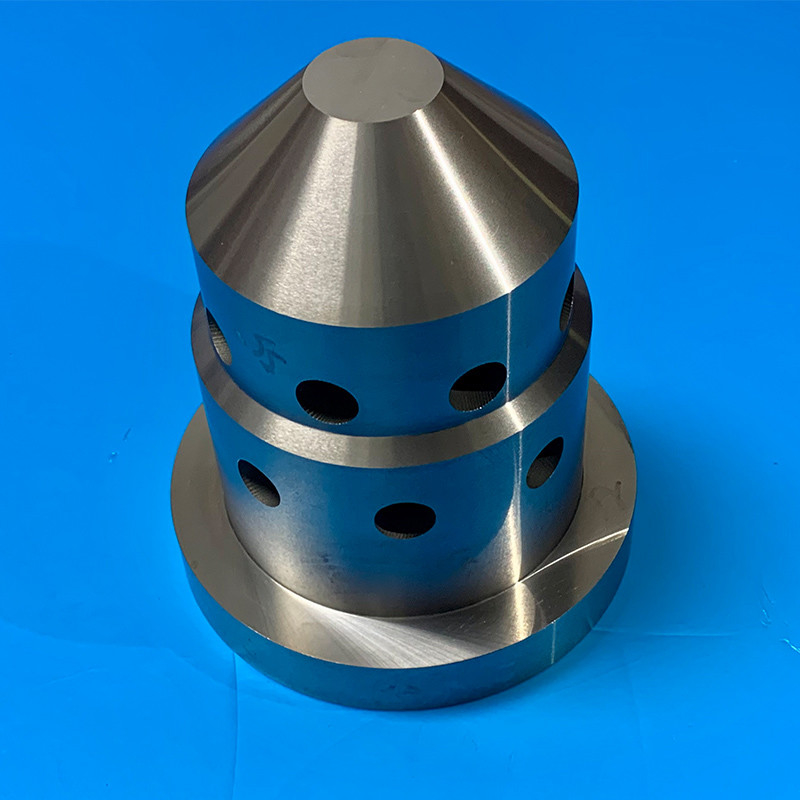

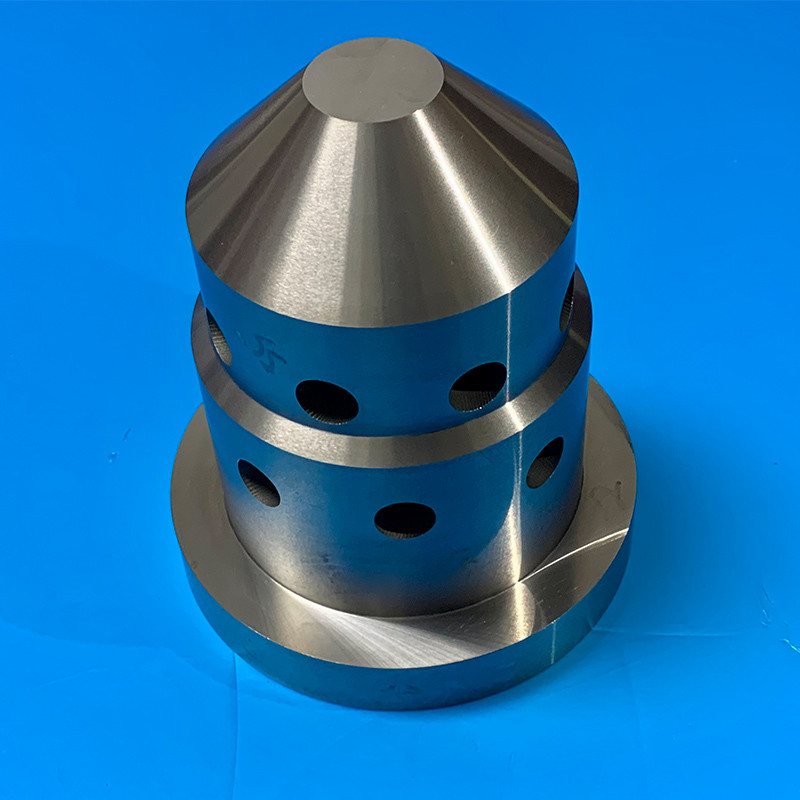

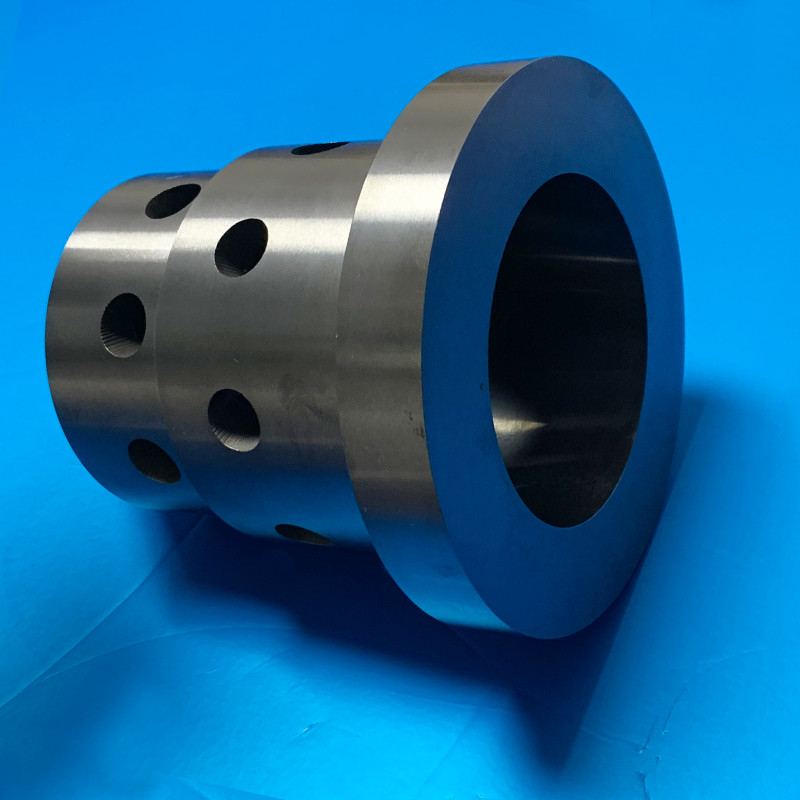

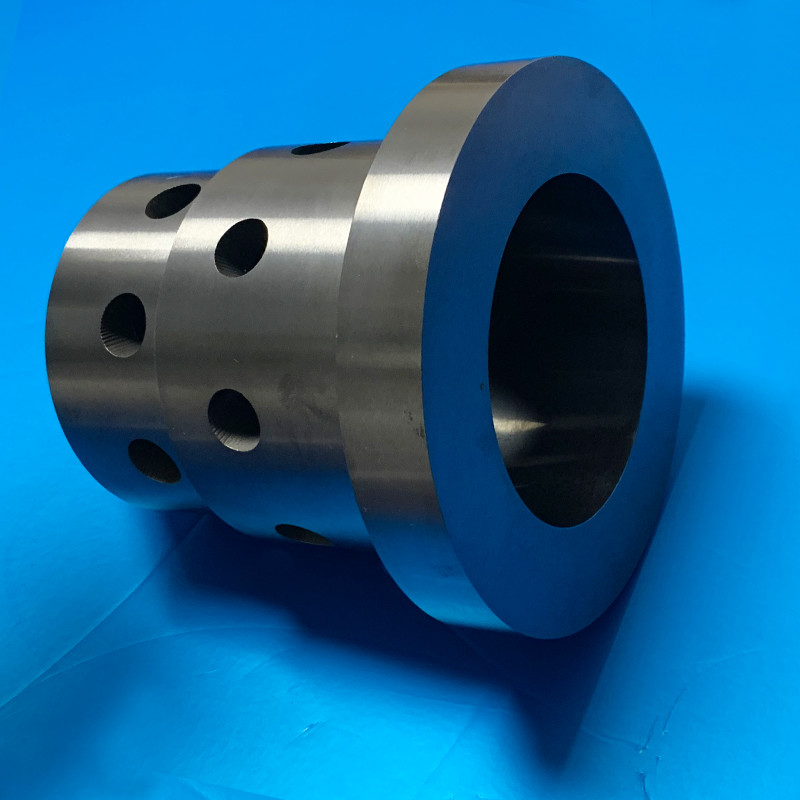

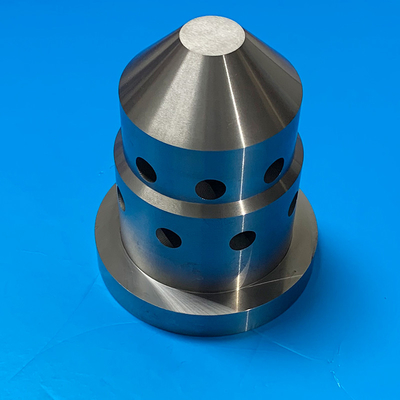

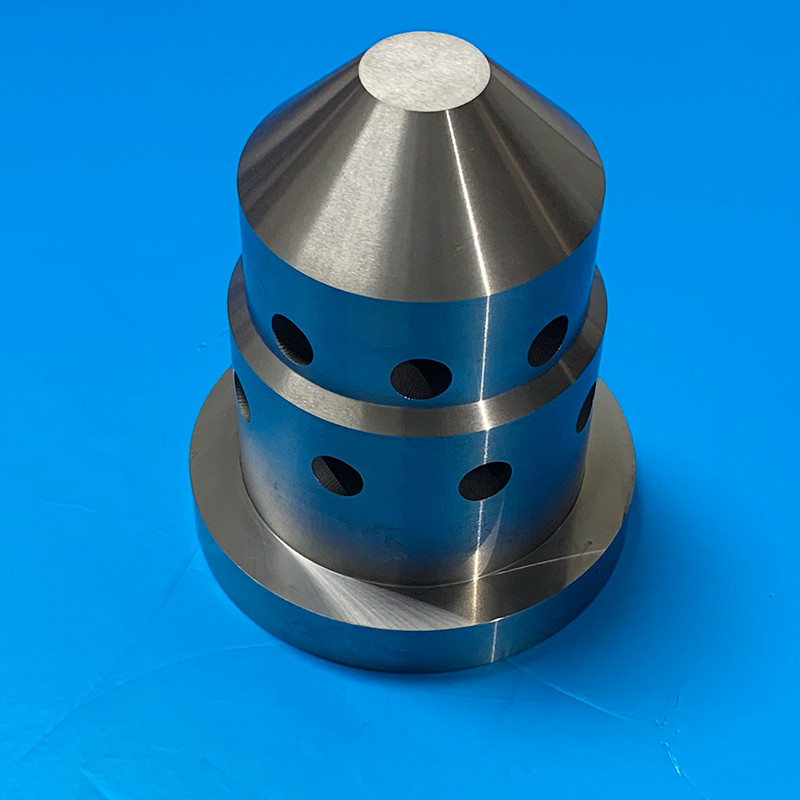

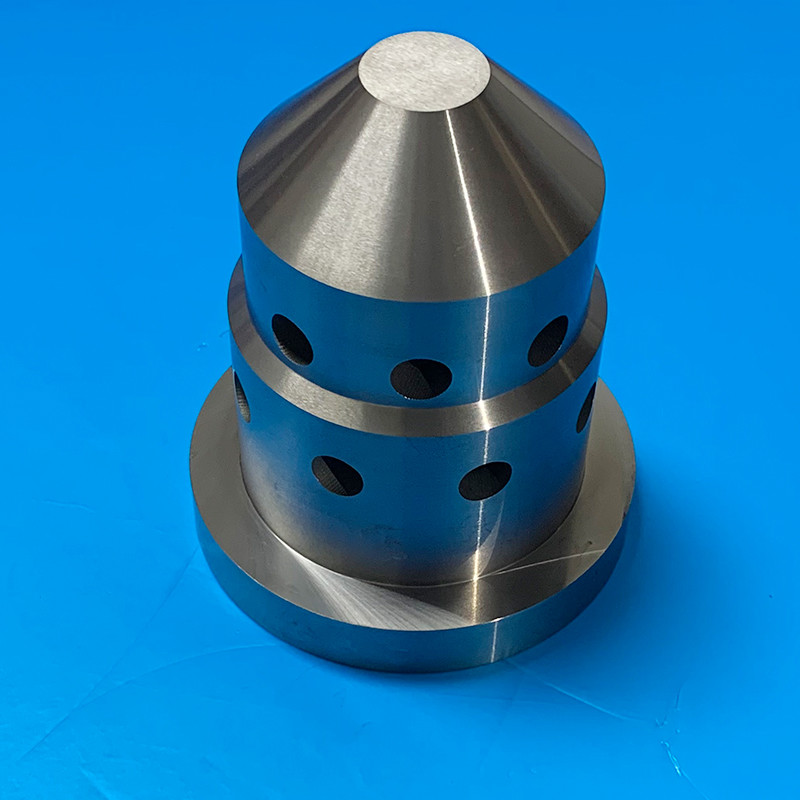

Huge Tungsten Carbide Honeycomb Nozzle for Oil and Gas Industry

This heavy-duty tungsten carbide honeycomb nozzle weighs 10KG per piece and features durable construction with exceptional wear resistance and precise fluid control capabilities. Designed specifically for the oil and gas industry, it optimizes production processes, improves operational efficiency, and ensures reliable performance across various applications.

Product Specifications

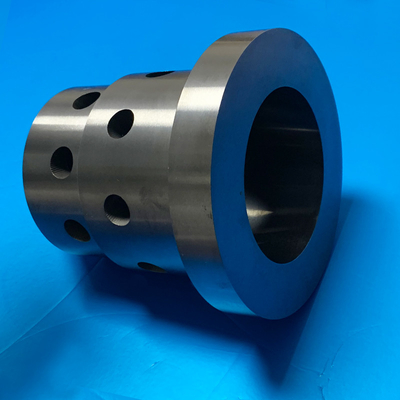

Function: This specialized component is engineered for oil and gas drilling, well stimulation, and fluid injection applications. It provides precise control over fluid flow, direction, and dispersion in demanding operational environments.

Material: Constructed from tungsten carbide, a composite material consisting of tungsten carbide particles bonded with a metallic binder (typically cobalt). This material offers exceptional hardness, superior wear resistance, and excellent high-temperature stability for rigorous oil and gas industry applications.

Honeycomb Structure Advantages

- Enhanced Fluid Dispersion: The hexagonal cell pattern creates uniform fluid distribution for efficient dispersion and comprehensive coverage

- Improved Flow Control: Interconnected cells regulate flow rate and direction, ensuring precise control during oil and gas operations

- Increased Surface Area: The honeycomb design maximizes surface area, promoting better mixing and interaction between fluid and surrounding environment

Key Performance Benefits

| Wear Resistance |

Tungsten carbide provides excellent wear resistance, ensuring extended nozzle longevity and durability under harsh operating conditions |

| Chemical Resistance |

Resistant to corrosion and chemical reactions, making it suitable for handling various fluids encountered in oil and gas operations |

| High-Temperature Stability |

Maintains structural integrity and performance at elevated temperatures, withstanding demanding thermal conditions |

| Precise Fluid Control |

Honeycomb structure combined with tungsten carbide properties enables accurate control of fluid flow, direction, and dispersion for efficient operations |

Manufacturer Profile

Zhuzhou Sanxin specializes in cemented carbide products including nozzles, bushings & sleeves, sealing rings, molds, inserts, mill rollers, and custom components. Cemented carbide is a composite hard alloy material created through powder metallurgy, combining refractory metal with a metallic binder.

These materials exhibit exceptional properties including high hardness, wear resistance, strength, and toughness, making them ideal for industrial parts and tools operating in harsh and aggressive environments. Tungsten carbide and tungsten alloy represent the primary forms of cemented carbide, also known as metal ceramic.

Machining Capabilities

Maximum Size: Φ85 × 1200mm

Minimum Size: Φ0.045 × 14mm

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!