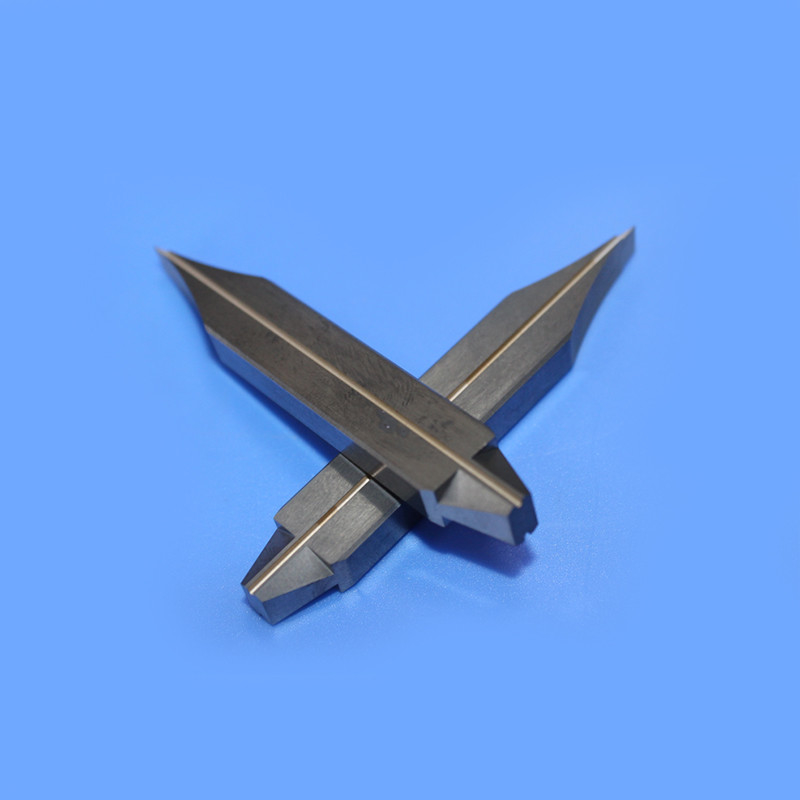

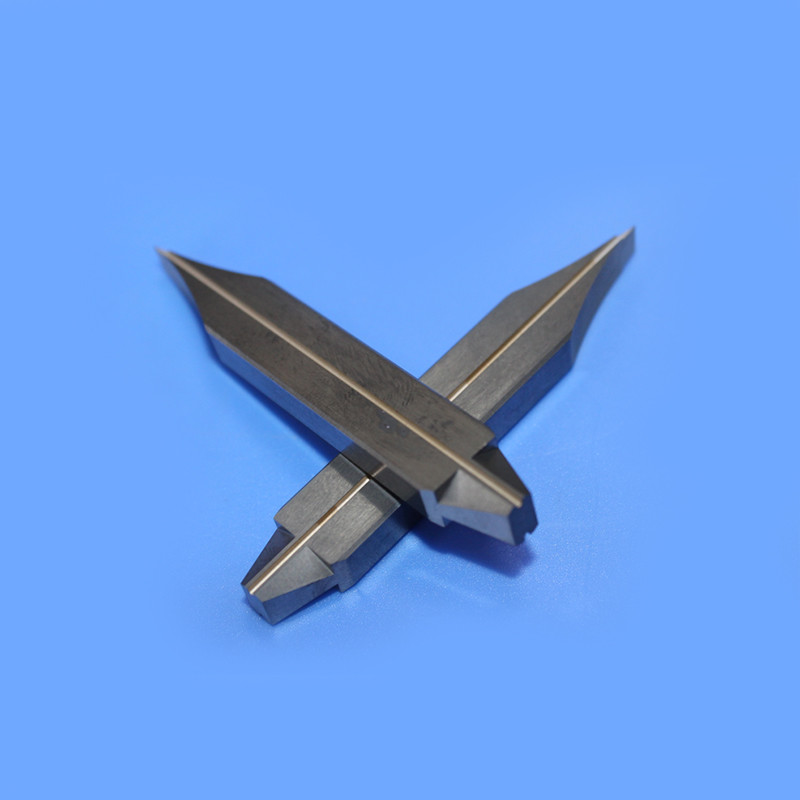

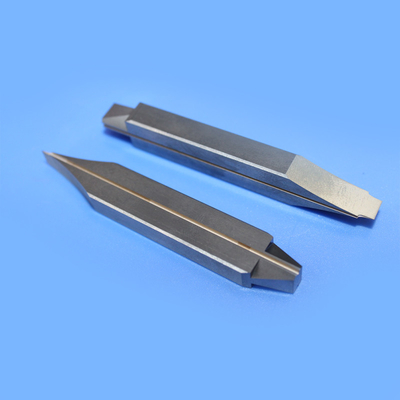

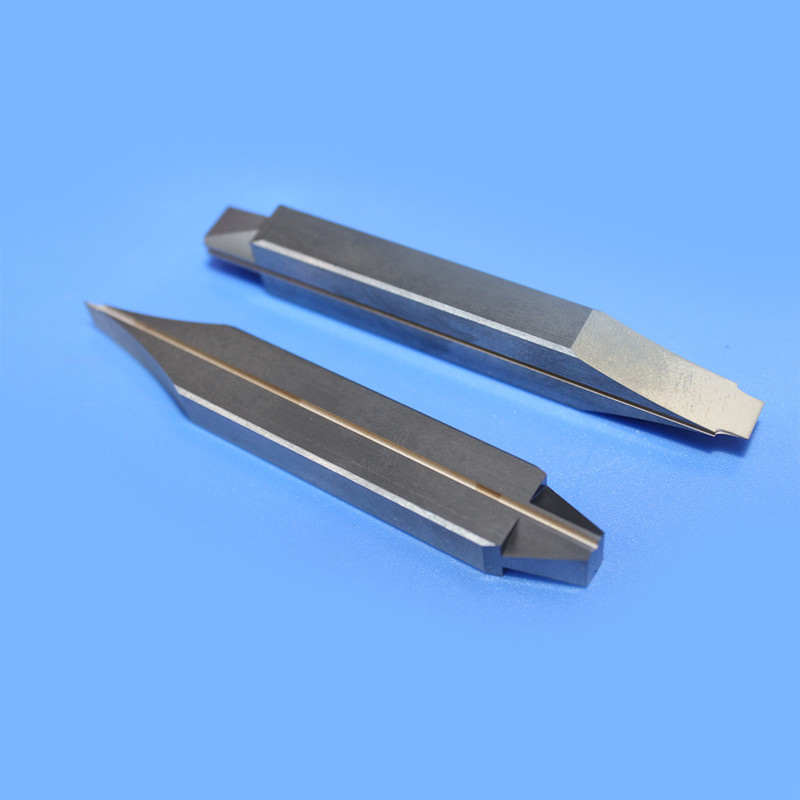

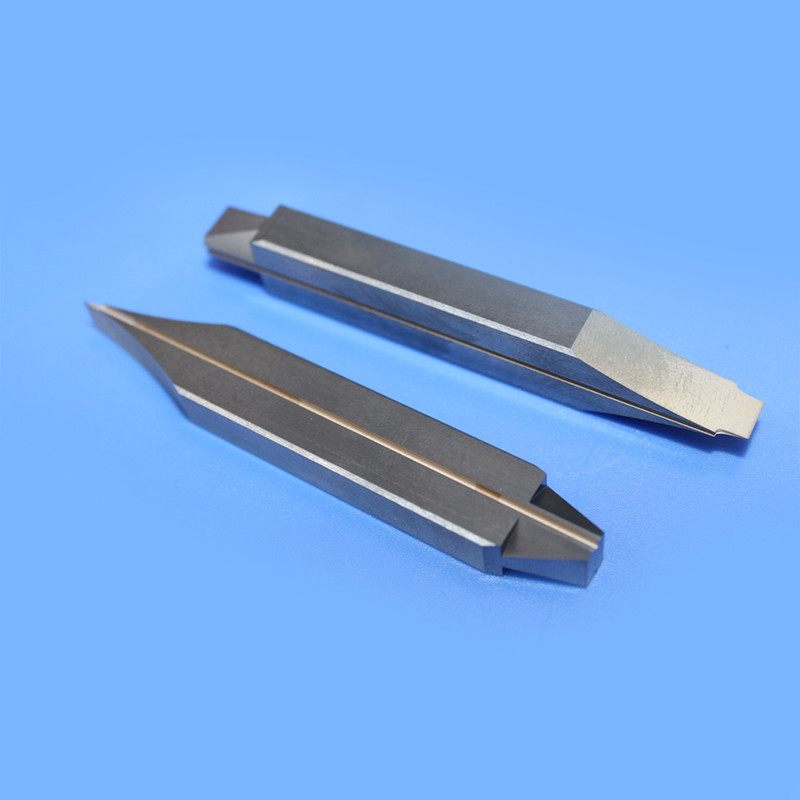

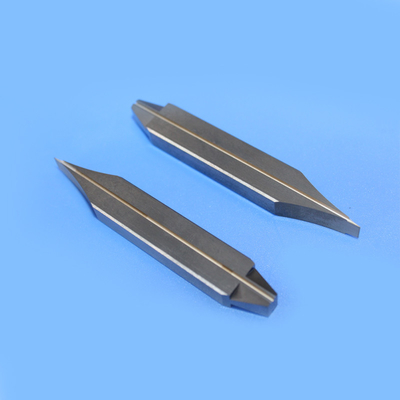

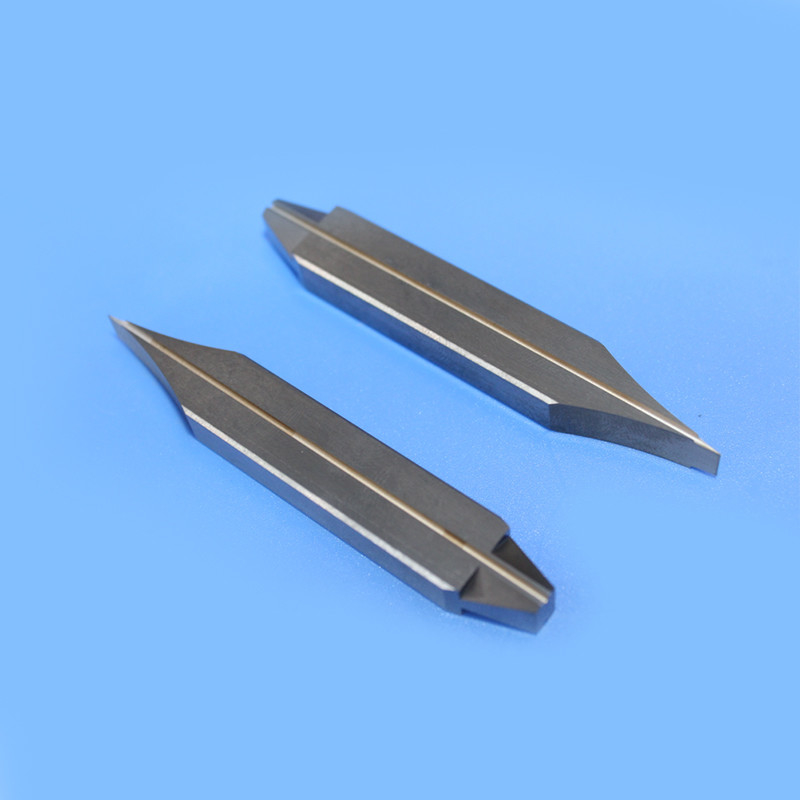

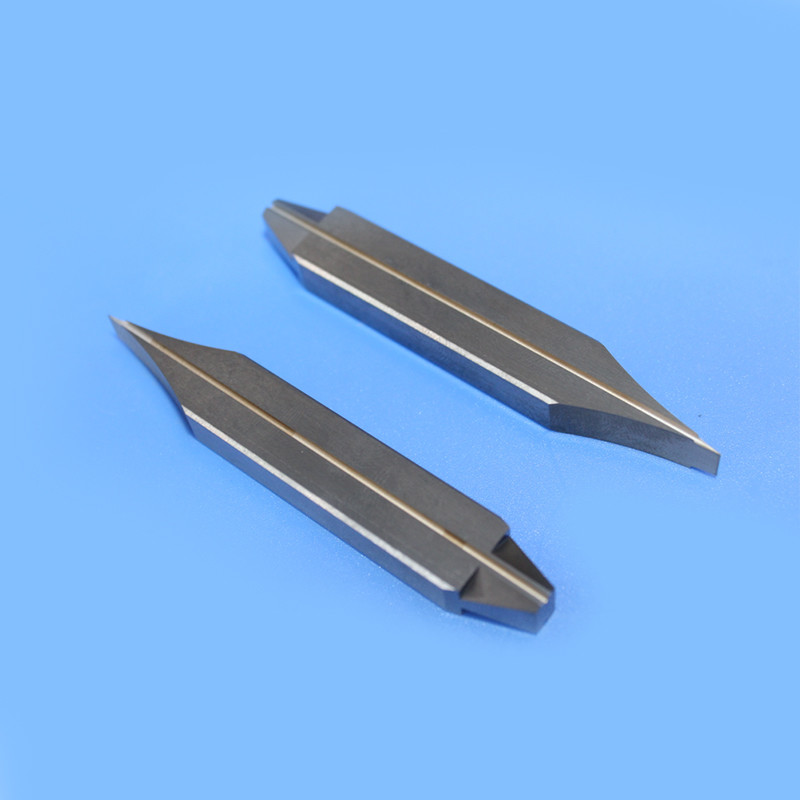

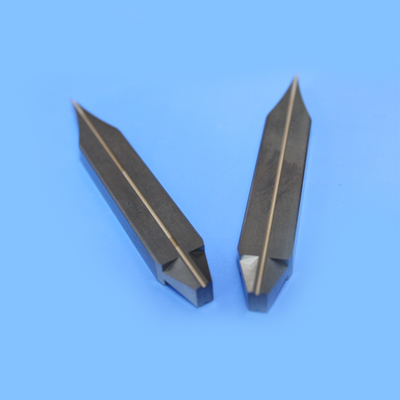

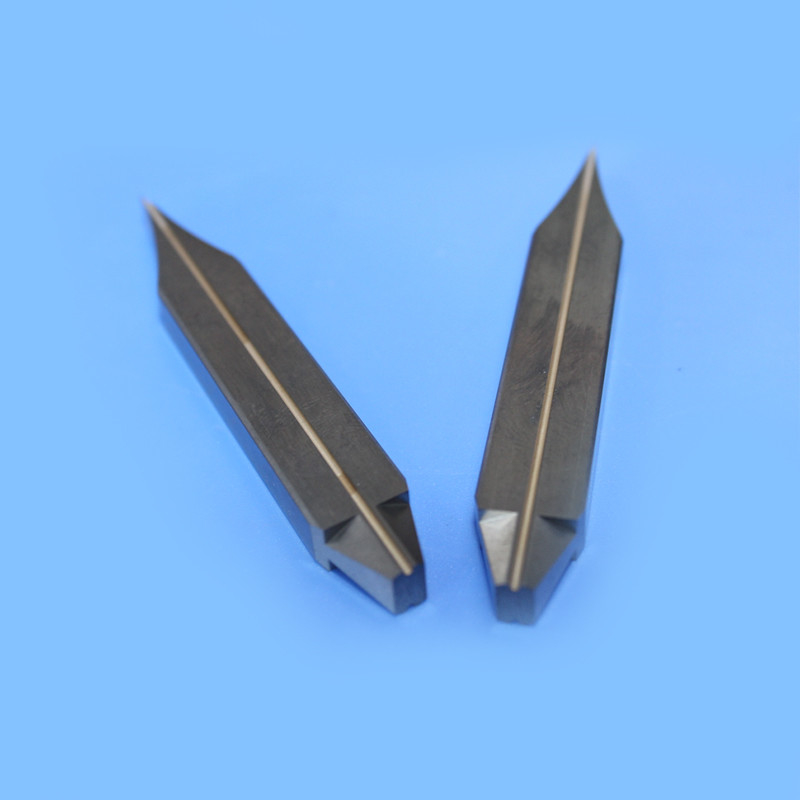

Ultimate Cemented Carbide Wire Guide Block with Grooves for Wire Processing

Cemented Carbide Wire Guide Blocks are essential components designed for wire processing and guiding applications. Manufactured from high-quality cemented carbide, these blocks facilitate smooth wire or cable passage during production processes, minimizing friction and wear to enhance operational efficiency and product quality.

Key Features

- Superior Wear Resistance: Cemented carbide construction provides exceptional durability, capable of withstanding prolonged, high-intensity use without performance degradation

- Precision Guiding: Engineered for accurate wire guidance, ensuring stable and precise positioning throughout machining operations

- Reduced Friction: Effectively minimizes friction and wear during wire passage, extending equipment and tool lifespan

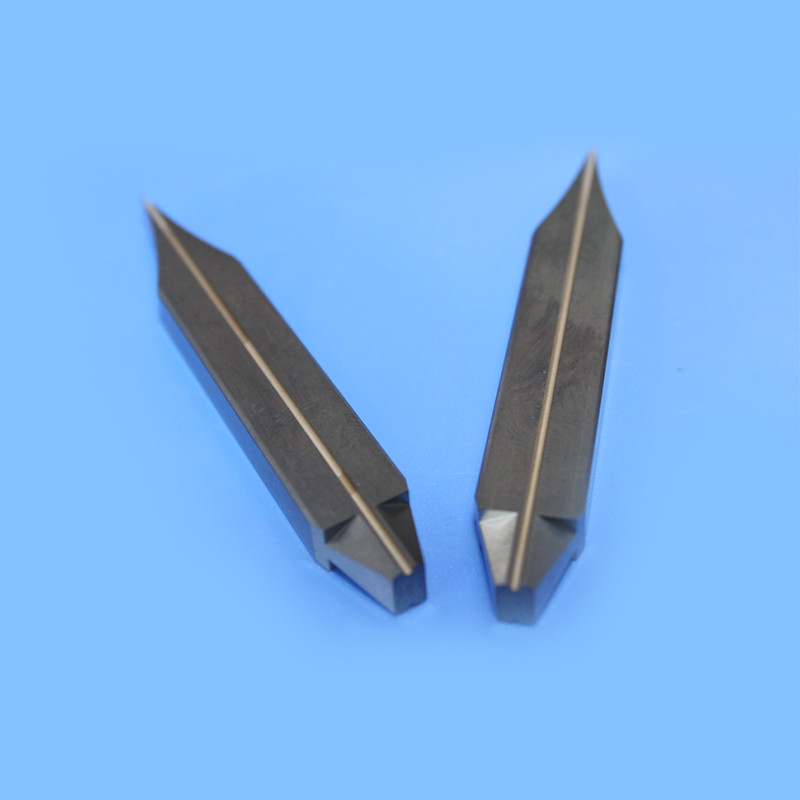

- Versatile Compatibility: Customizable designs accommodate various wire diameters and material characteristics to meet diverse processing requirements

These cemented carbide wire guide blocks are crucial components in industries including cable manufacturing, wire production, and steel wire processing, significantly enhancing production efficiency and machining quality in industrial manufacturing applications.

Manufacturer Expertise

Sanxin Tungsten Carbide Manufacture brings 20 years of specialized experience in carbide bits, blades, and OEM parts production.

| 1 |

National high-tech enterprise certification |

| 2 |

Processing high tolerance accuracy ±0.002mm |

| 3 |

Wear-resistant, heat-resistant and anti-corrosion properties |

Material Specifications

Tungsten Carbide Grade: K20, K10, K30 or other specified high-quality carbide grades

Non-magnetic carbide material is also available for forming moulds of magnetic materials, offering high hardness, extended service life, excellent wear resistance, and strong corrosion resistance.

Product Advantages

Cemented carbide wearing parts, also known as wolfram carbide (WC) parts, are premium components in the hardware machinery industry. Their superior performance characteristics include:

High hardness, excellent toughness, superior high and low temperature wear resistance, minimal adhesion, strong corrosion resistance, high thermal conductivity, low friction coefficient, acid and alkali corrosion resistance, and easy maintenance.

With exceptional toughness, high temperature resistance, and superior wear resistance, these components deliver service life 10-50 times longer than standard metal parts.

Beyond ISO 9001:2015 Quality Management System certification and National high-tech enterprise certification, we hold more than 20 patent certificates.

| 1 |

100% virgin wolfram carbide materials |

| 2 |

Fine-grain, including ultra fine grain tungsten carbide options |

| 3 |

Excellent wear, abrasion, and corrosion resistance |

| 4 |

High fracture strength and superior hardness |

| 5 |

Extended service life |

| 6 |

Varied cemented carbide material grades |

| 7 |

Competitive EXW factory pricing |

| 8 |

Customization services available |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!