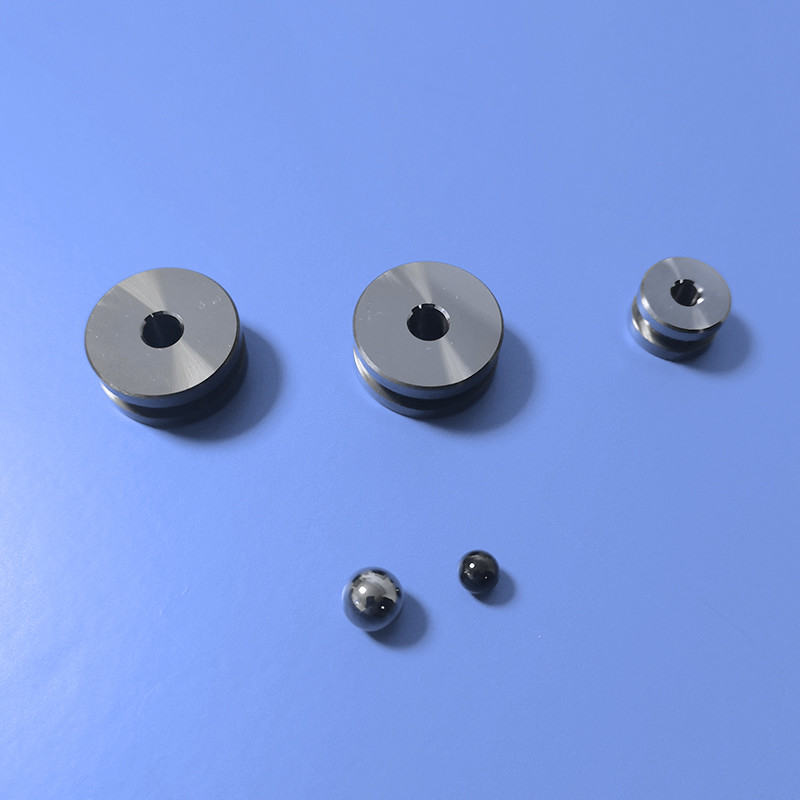

Cemented Carbide Sleeve Valve Seat and Valve Core for Oil & Gas Industry

Precision-engineered cemented carbide sleeve valve seats and valve cores designed specifically for demanding oil and gas industry applications, offering superior performance in extreme operating conditions.

Valve Ball Evolution and Structure

Hard alloy ball valves have evolved from traditional plug valves, featuring spherical closure elements that rotate around the valve stem axis. These components enable precise control for cutting off, distributing, and altering flow direction within pipeline systems. Specially designed ball valves also provide fluid flow regulation capabilities.

Oil and Gas Industry Applications

Tungsten carbide valve seat pairs are extensively utilized in petroleum drilling operations, deep-sea oil drilling applications, and pump valve systems. These critical components play a vital role in oil pump systems where reliability and durability are paramount.

Operating Environment and Performance Requirements

The petroleum drilling industry operates under extreme conditions including sand-filled wells, heavy oil wells, and high-pressure anti-sand oil wells. These environments contain corrosive elements such as water, gas, wax, and sand, demanding superior sealing capabilities, exceptional wear resistance, and excellent corrosion resistance from valve ball and seat components.

Tungsten Carbide Valve Ball Advantages

Tungsten carbide valve balls demonstrate outstanding performance characteristics including high density, superior wear resistance, and excellent corrosion resistance, making them ideally suited for petroleum extraction and transportation applications. In oil drilling pump systems, their exceptional hardness, density, strength, stable chemical properties, superior bending resistance, and impact toughness exceed performance levels of alternative materials.

During petroleum extraction and transportation processes, common failure modes for pump valve balls include wear, corrosion, fatigue cracks, and fragmentation. The hard alloy tungsten steel valve seat and valve head, with their superior hardness, density, strength, stable chemical properties, exceptional bending resistance, and impact toughness, significantly enhance drilling efficiency, extend tool lifespan, and reduce operational costs.

Tungsten Carbide Sleeve Technical Specifications

As a premier super-hard metal, cemented carbides offer exceptional high-temperature resistance and physical stability, particularly as high-temperature mold materials suitable for extreme environmental production and processing requirements.

High-Temperature Performance Standards

- Long-term high temperature tolerance (up to 800°C) without deformation

- Air cooling compatibility without bursting

- Precision machining with parallelism of upper and lower sides <0.003mm

Industrial Applications and Benefits

Carbide molds are widely used in the hardware machining industry due to their exceptional performance characteristics including high hardness, superior toughness, excellent high and low temperature resistance, outstanding wear resistance, low adhesion, good corrosion resistance, high thermal conductivity, low friction coefficient, acid and alkali corrosion resistance, rust-free operation, and easy maintenance. The cemented carbide mold typically provides 10 to 50 times longer service life compared to standard alloy molds.

Common applications include hard alloy stamping dies, carbide grading molds, powder pressing dies, battery shell stamping dies, stainless steel mobile phone shell stamping dies, bicycle shaft bushings, shaft bowl stamping dies, shaped carbide molds, carbide shrinkage dies, carbide wire drawing dies, carbide dies, hard alloy thimbles, carbide extrusion dies, cold dies for bolts and nuts, frame stamping dies, and various specialized tooling applications.

Technical Processing Parameters

Cemented carbide is particularly suitable for mold materials with special application requirements. However, compared to traditional steel molds, the production and processing of cemented carbide molds requires more comprehensive equipment and advanced technical expertise to ensure precision manufacturing. High-temperature cemented carbide molds are produced according to specific drawing requirements, with processing timelines spanning from raw material blank pressing and sintering through to finished product precision machining. Customers with specific requirements should plan accordingly to ensure adequate processing time and avoid production delays.

Using high-quality materials significantly improves production efficiency. We provide high-temperature hard alloy mold tungsten steel mold flanges that meet custom requirements. High wear resistance is essential for die products, particularly progressive dies, combined dies, and multi-station dies. The superior performance of tungsten steel die cavity materials ensures long-term operational reliability.

As a premier tool material, tungsten steel has become the preferred choice for die products due to its exceptional hardness, strength, and wear resistance characteristics. We provide non-standard customized cemented carbide die large diameter cavities according to specific customer drawing requirements, with precision tolerances that meet operational specifications.

Conventional Cemented Carbide Material Properties

| Parameter |

Specification |

| Grain size (um) |

1.0 ~ 2.0 |

| Cobalt content (Co%) |

8.0 ~ 10 |

| Density (g/cm³) |

14.41 ~ 14.95 |

| Hardness (HRA) |

89.5 ~ 93 |

| Bending strength (Mpa) |

3200 ~ 4500 |

| Young's modulus (Gpa) |

570 ~ 620 |

| Compressive strength (Mpa) |

4700 |

For specialized requirements, we provide carbide products tailored to specific application conditions and performance specifications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!