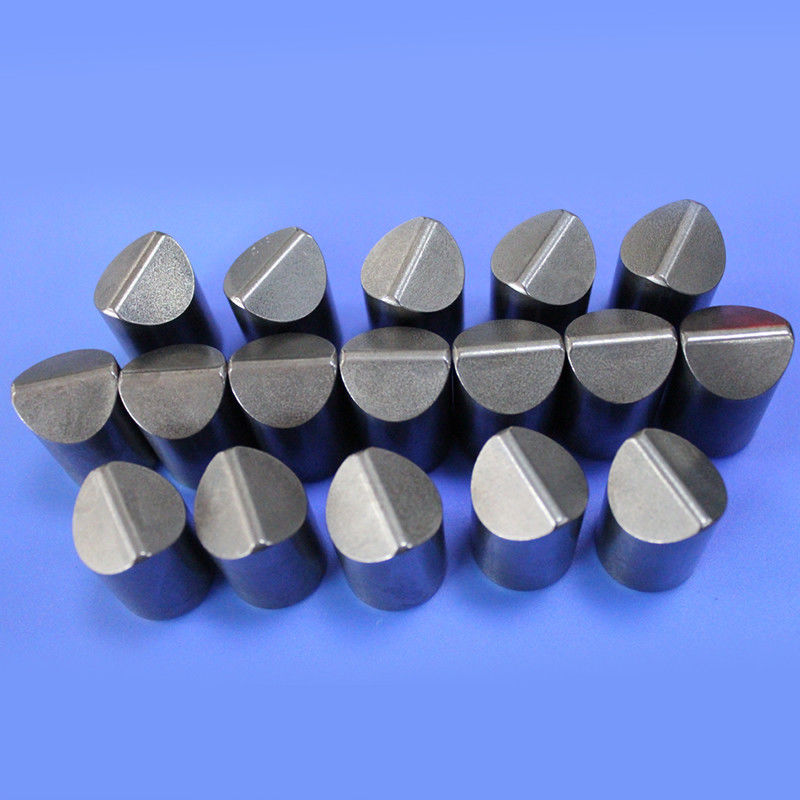

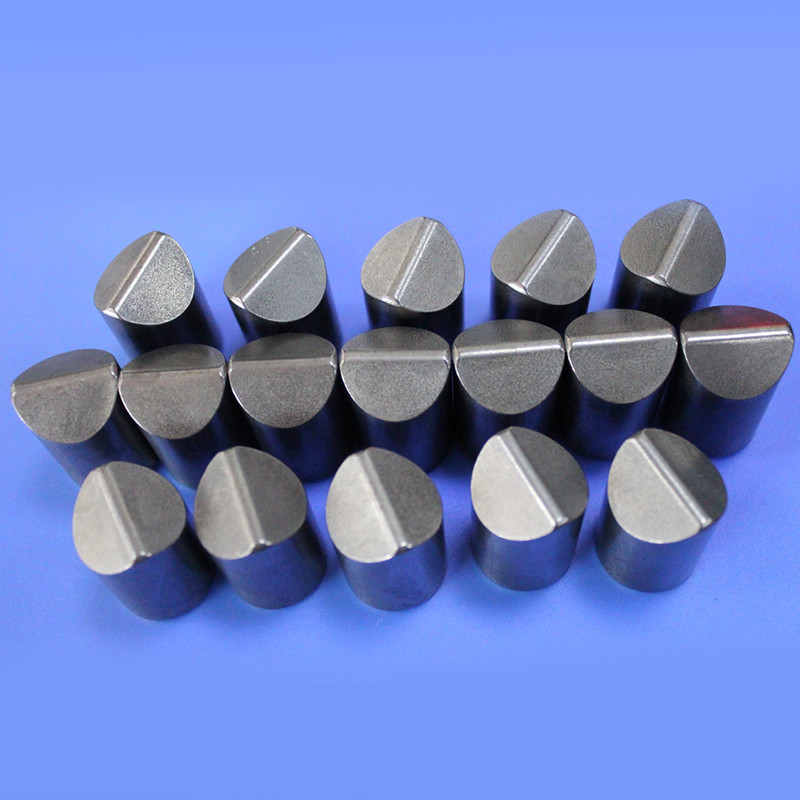

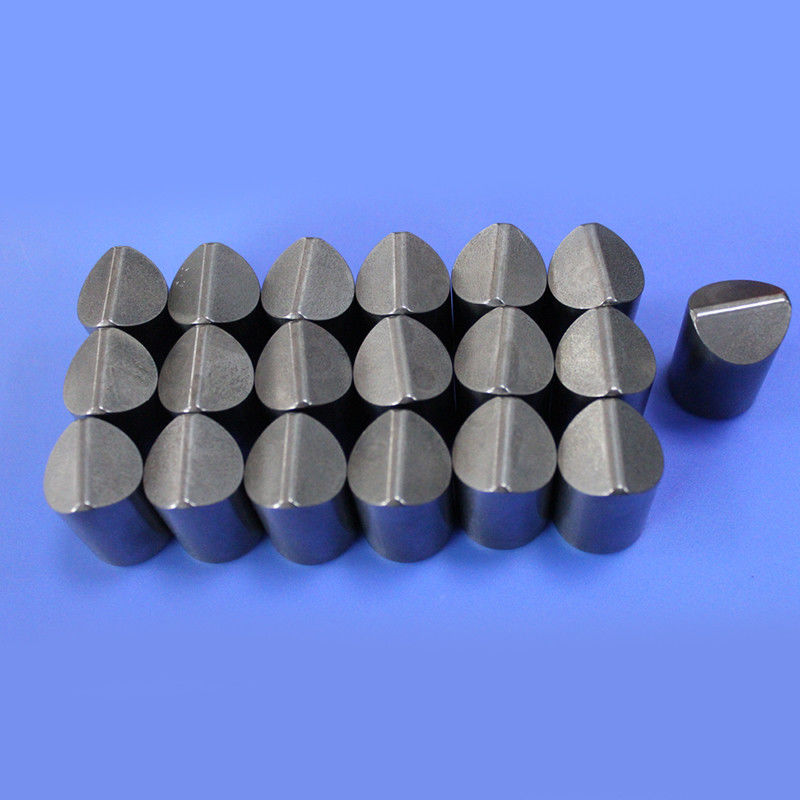

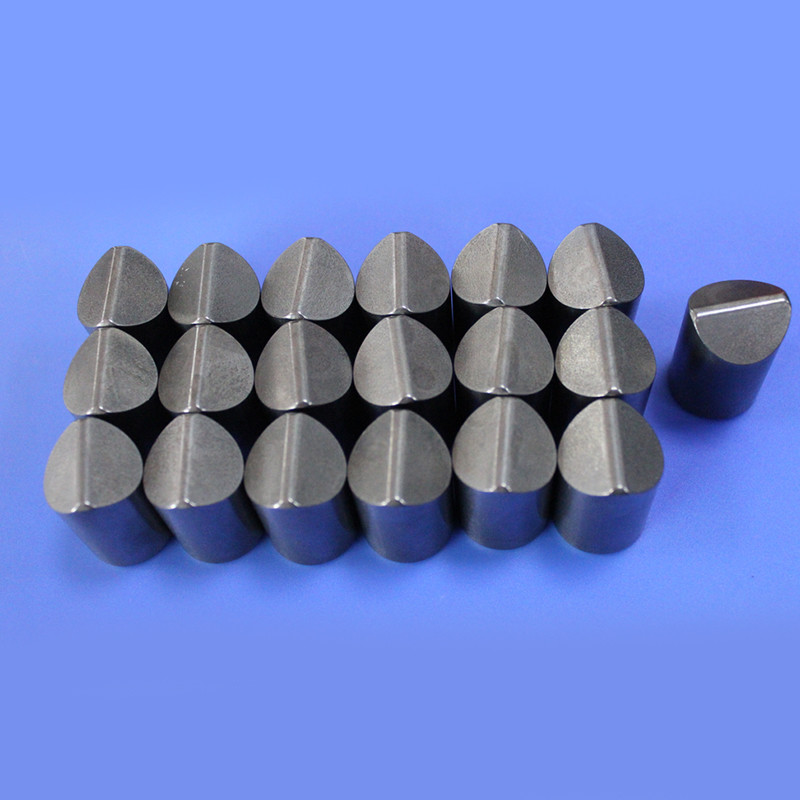

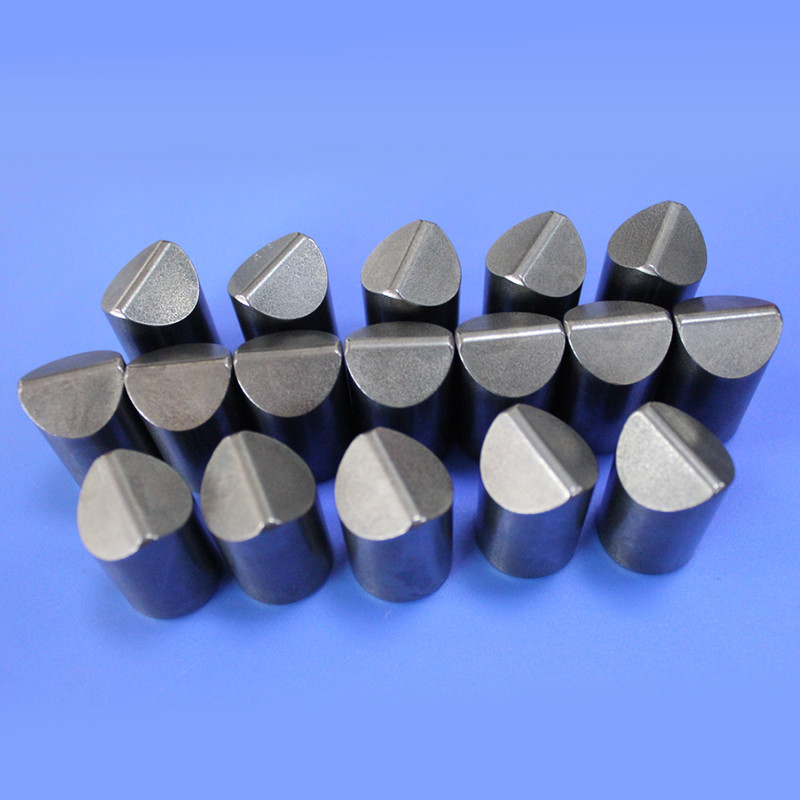

Abrasion Resistant Machinery Spare Parts Tungsten Carbide Button Bits

Tungsten Carbide inserts and carbide buttons are engineered for demanding hard rock applications. As industrial teeth components, they provide exceptional wear resistance for heavy-duty tools. Custom specifications are available upon request.

Material Grades & Specifications

| Grade |

Density (g/cm³) |

Hardness (HRA) |

MPa |

| KZ40C |

13.30~13.45 |

87.0~88.0 |

≥3000 |

| KZ30A |

14.03~14.17 |

88.0~89.0 |

≥3000 |

| KZ35 |

13.85~14.04 |

87.5~88.9 |

≥2800 |

| YG20 |

13.45~13.65 |

≥84.5 |

≥2480 |

| YG15 |

13.95~14.15 |

≥86.5 |

≥2400 |

| YG16C |

13.75~13.95 |

≥84.0 |

≥2640 |

| YG13C |

14.15~14.35 |

≥85.5 |

≥2450 |

Key Product Features

| Carbide Grade |

YG8 material, density 14.7g/cm³, hardness HRA89 |

| Assembling Units |

HPGR cemented carbide segments |

| Assembling Method |

Primarily welding |

| Replacement |

Replaceable design |

| Performance Requirements |

Excellent impact resistance and wear resistance |

Material Properties

- High hardness and superior wear resistance

- High elastic modulus

- Exceptional compressive strength

- Excellent chemical stability (resistant to acid/alkali corrosion and high temperature oxidation)

- Moderate impact toughness

- Low expansion coefficient with thermal and electrical conductivity similar to iron alloys

Assembly Methods

Brazing

A common method using filler metal with lower melting point than carbide and base material. Buttons are positioned on the tool, then brazing material is heated to melt and bond carbide to the tool substrate.

Press-Fit

Precisely manufactured buttons fit into corresponding cavities on the tool substrate. Buttons are press-fitted using hydraulic presses or mechanized equipment for a tight, secure bond.

Adhesive Bonding

Specialized adhesives applied to button or substrate, then positioned and pressed into place. Adhesive cures to form a strong bond securing the carbide.

Mechanical Fastening

Buttons attached using screws, bolts, or rivets through pre-drilled holes in both carbide buttons and tool substrate.

Sintering

Buttons sintered directly onto tool substrate during manufacturing using heat and pressure to create a strong metallurgical bond at molecular level.

Welding

Melting carbide and/or substrate material along joint area, allowing solidification to create a fused bond between materials.

The selection of assembly method depends on tool type, button design, material compatibility, and required bond strength and durability. Each method offers distinct advantages in cost, efficiency, and application-specific requirements.

Applications

Coal mining, construction drilling, excavation, road milling and planing, and stone crushing machine rock breaking applications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!