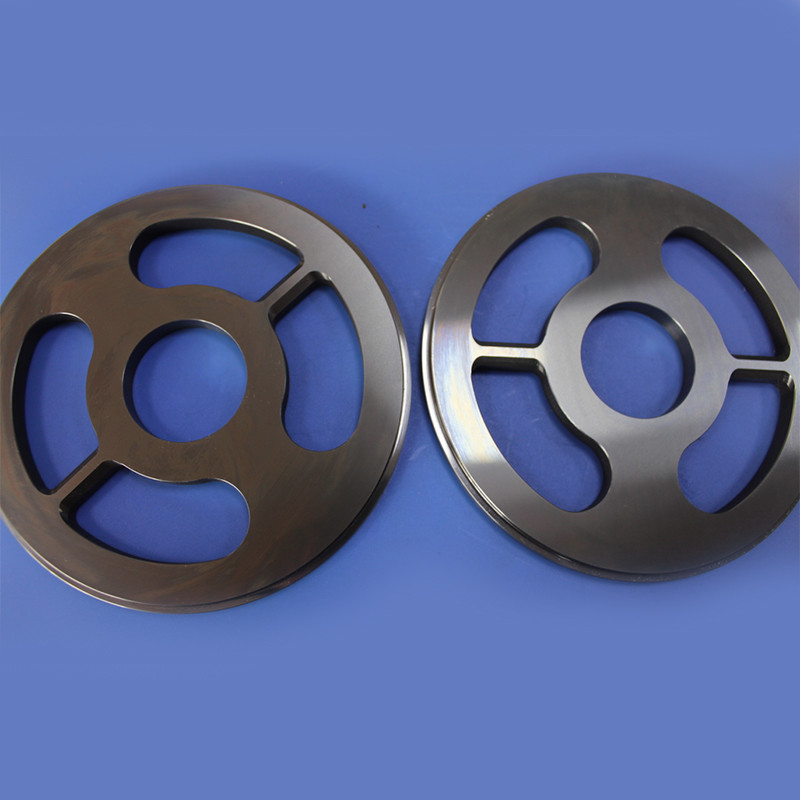

Pump Industry Flow Disc Wear Parts

High Precision Tungsten Carbide Material Components

Our precision tungsten carbide pump industry flow disc components include hard alloy wear parts, customized side plate inserts, and flow disc inserts. These specialized components are engineered for submersible electric pumps, delivering high-precision performance and exceptional wear resistance.

Pump Industry Applications

Water pumps are mechanical devices designed to transport liquids and increase fluid pressure by transferring mechanical energy from power sources to the liquid. Our tungsten carbide components serve diverse applications including transportation of water, oil, acids, alkalis, emulsions, suspensions, and liquid metals across various pump types.

Supported Pump Types

- Self-priming pumps

- Submersible pumps

- Axial flow pumps

- Mixed flow pumps

- Integrated pump stations

- Chemical pumps

- Slurry pumps

- Submersible sewage pumps

- Centrifugal pumps

- Vacuum pumps

Technical Specifications

Hard Alloy Side Plate Insert: φ138.5*φ38.5*7-φ23.4*3-φ4-4*8

Hard Alloy Flow Disc Insert: φ138.5*φ38.5*R54.7-R31.3-R11.7-R4-4*2-φ4-4*8

Precision Requirements

These pump industry hard alloy disc inserts meet stringent specifications including flatness of 0.001, directional parallelism, positional accuracy, and coaxiality of 0.02. The disc surfaces undergo meticulous grinding and polishing to achieve a mirror finish with Ra0.2 cleanliness rating. Backside locating pin holes ensure precise assembly alignment for optimal performance.

Material Properties

Manufactured through powder metallurgy, our tungsten carbide material delivers exceptional physical properties including high hardness, superior wear resistance, and excellent corrosion resistance, making it ideal for demanding pump industry environments.

Sanxin Tungsten Carbide Manufacturing

Specializing in carbide bits, blades, and OEM parts for over 20 years

| National high-tech enterprise certification |

| Processing high tolerance accuracy ±0.002mm |

| Wear-resistant, heat-resistant and anti-corrosion properties |

Material Grades

Tungsten Carbide Grades: K20, K10, K30 or other appointed high quality carbide grades. Non-magnetic carbide material is also available for forming moulds of magnetic materials, offering high hardness, extended service life, excellent wear resistance, and strong corrosion resistance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!