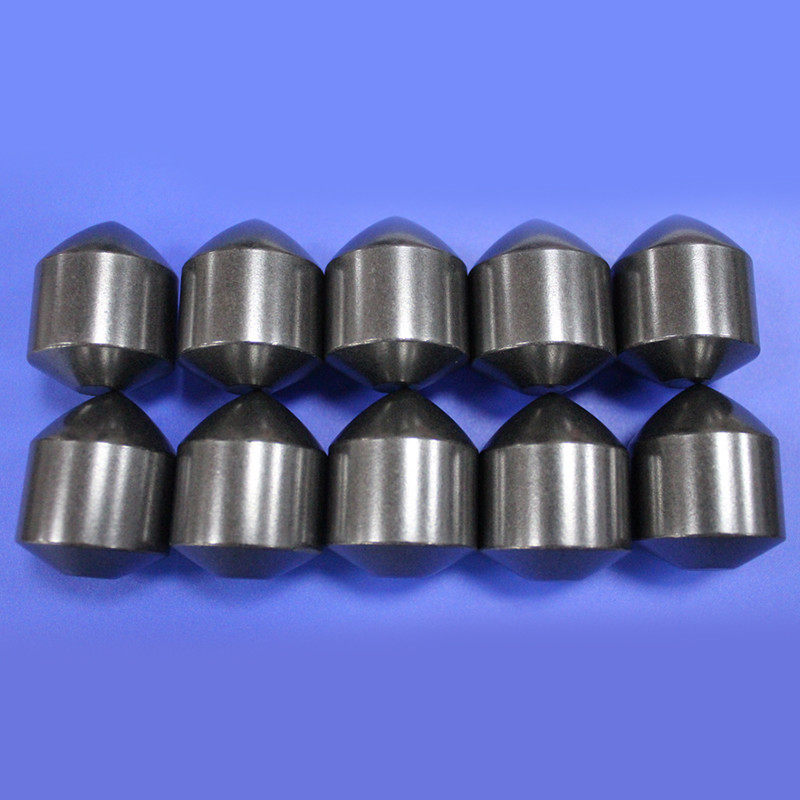

High Durability Carbide Teeth Inserts Buttons Carbide Cutting Tools

Tungsten carbide inserts and carbide buttons are engineered for demanding hard rock applications. Our nano cemented carbide features WC grain sizes smaller than 0.2μm, delivering superior hardness and strength compared to standard cemented carbide.

This advanced material effectively addresses the challenges of ultra-high speed cutting for difficult-to-machine materials including superalloys, titanium alloys, composite materials, and hardened steel. The result is significantly improved machining efficiency, making it the preferred tooling material in aerospace and high-end equipment manufacturing industries.

Product Reference Drawing

Cemented carbide is a composite material manufactured through powder metallurgy, combining refractory metal hard compounds (WC, TiC) with bonding metals (Co, Ni, Fe). This composition provides exceptional properties including high hardness, superior wear resistance, excellent strength, high modulus of elasticity, low thermal expansion coefficient, outstanding red hardness, and stable chemical characteristics.

Our extra coarse-grained cemented carbide features WC grain sizes exceeding 6μm, offering enhanced toughness, thermal fatigue resistance, and wear resistance compared to standard coarse-grained variants. This makes it ideal for extreme working conditions in shield tunneling, mining, stamping dies, cold heading dies, rolls, and similar applications, significantly improving product reliability.

Coal mining tungsten carbide buttons can be customized to match your specific drilling tool requirements. Designed for complex underground mining environments with variable geological components and high-power equipment generating substantial propulsion and shear forces, these buttons provide exceptional impact resistance, heat resistance, and wear resistance.

J Type Buttons Specifications

| Type |

D |

H |

h |

SRI |

SR2 |

r |

| ZJ25X38/P/KP |

25 |

38 |

25 |

2 |

50 |

3 |

| ZJ25X34/P/KP |

25 |

34 |

21 |

2 |

50 |

3 |

| ZJ24X30/P/KP |

24 |

30 |

18 |

2 |

48 |

3 |

| ZJ22X32/P/KP |

22 |

32 |

21 |

2 |

44 |

2.5 |

| ZJ19X26/P/KP |

19 |

26 |

16.5 |

2 |

38 |

2.5 |

| ZJ17X23/P/KP |

17 |

23 |

14.5 |

2 |

34 |

2 |

| ZJ16X25/P/KP |

16 |

25 |

17 |

2 |

32 |

2 |

Standard Specifications

| Dimensions (mm) |

Density (g/cm³) |

Hardness (HRA) |

TRS (Mpa) |

Diameter: 20

Height: 25 |

14.50 |

87.50 |

2400 |

Diameter: 22

Height: 35 |

14.50 |

86.00 |

2480 |

Diameter: 24.8

Height: 33 |

14.50 |

86.50 |

2600 |

Diameter: 25

Height: 35 |

|

|

|

Diameter: 26.5

Height: 38 |

|

|

|

Applications

Polyconical, parabolic, and mushroom tungsten carbide buttons represent the standard shapes for coal mining applications.

These tools are suitable for welding in coal mining operations, coal mining machinery in mid-soft rock formations, tunnel excavation in hard rock formations, drilling on extra hard rock formations, and tunnel excavation in complex geological conditions.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!