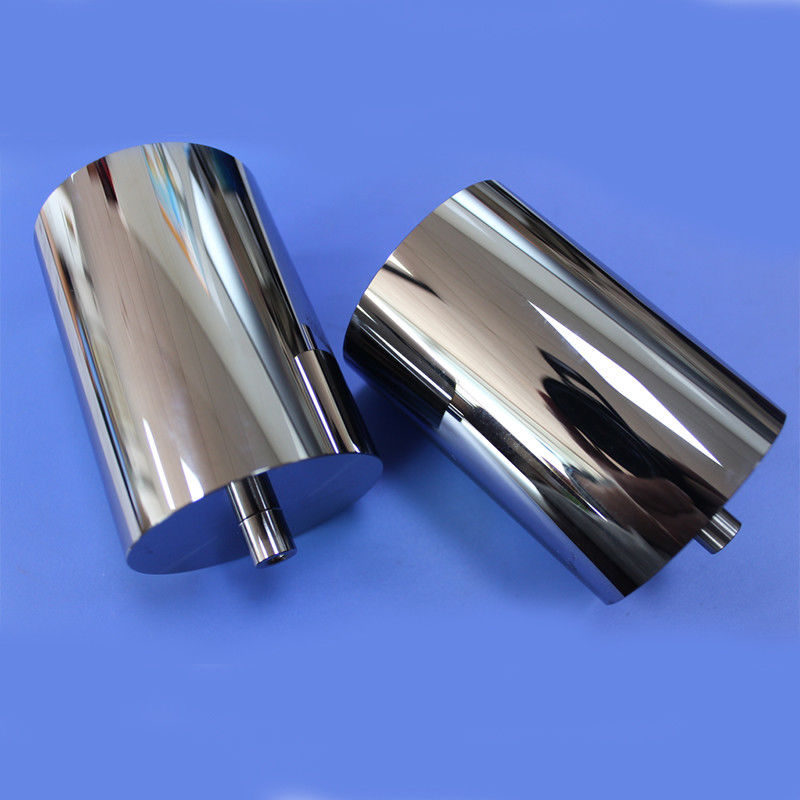

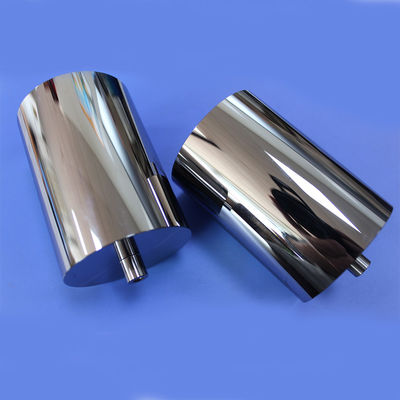

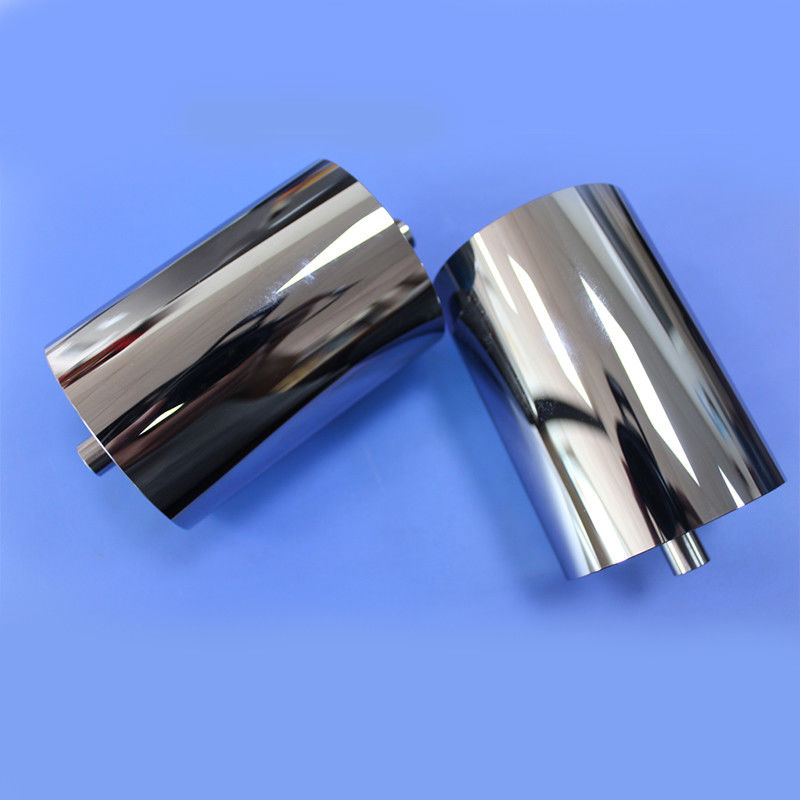

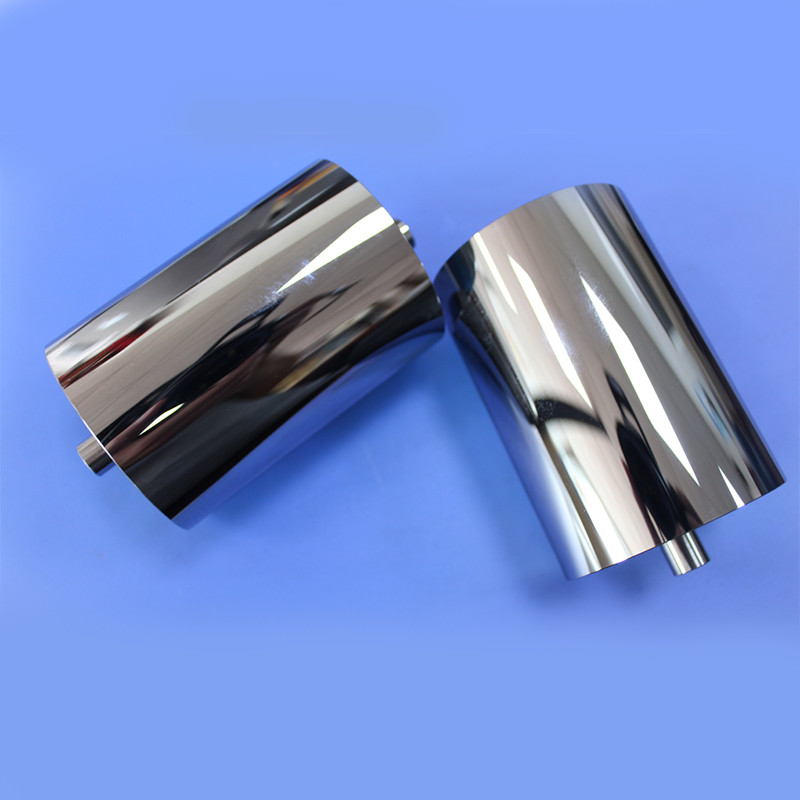

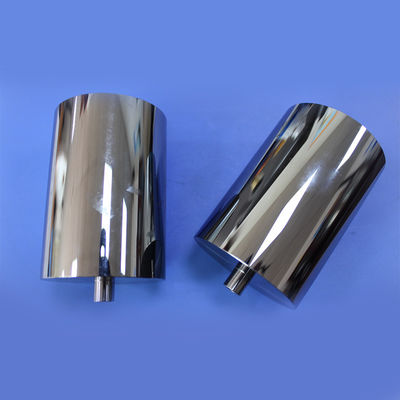

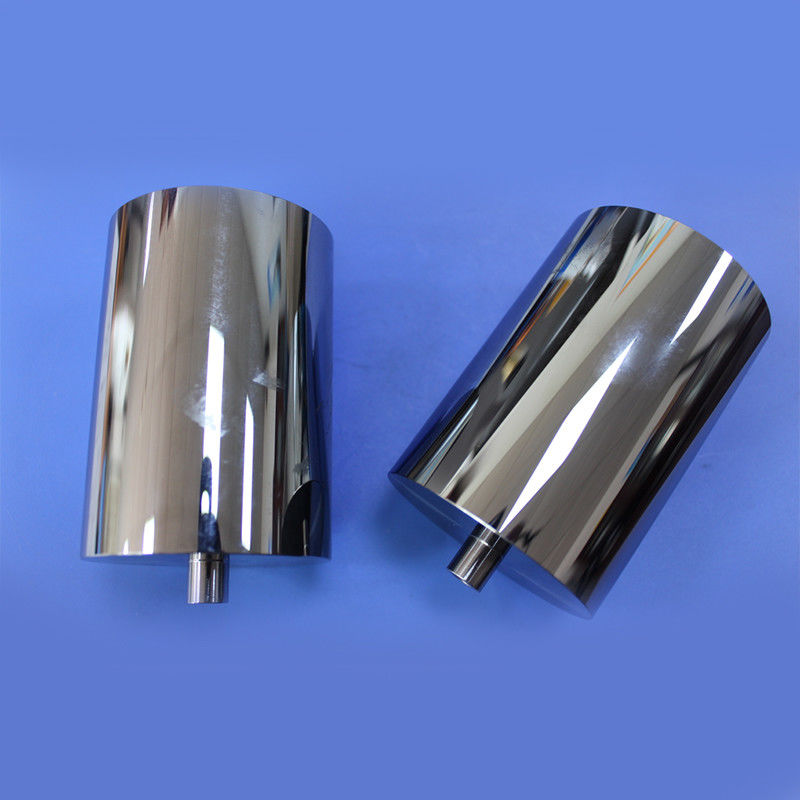

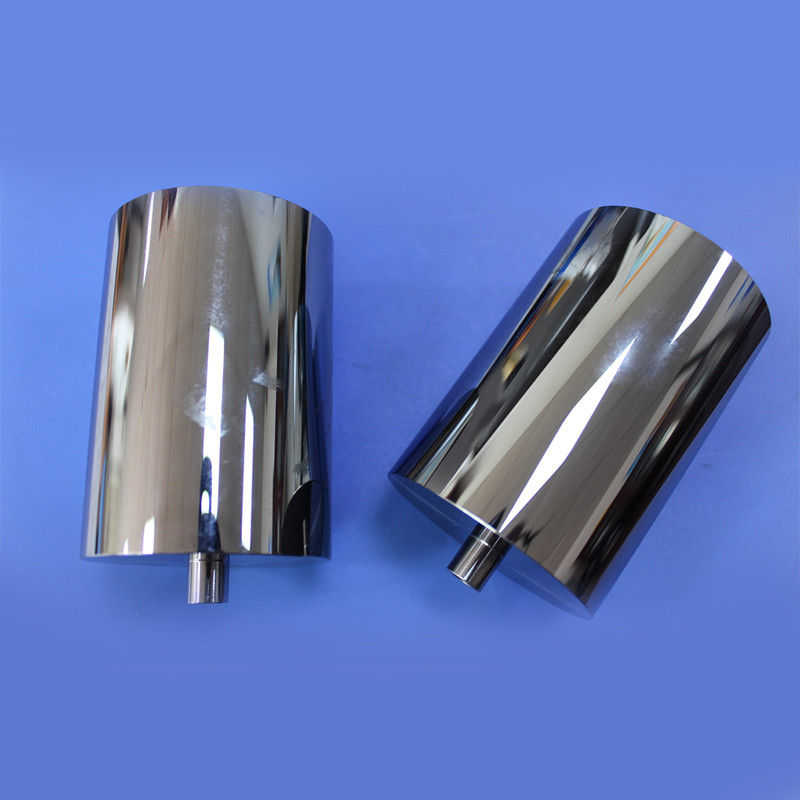

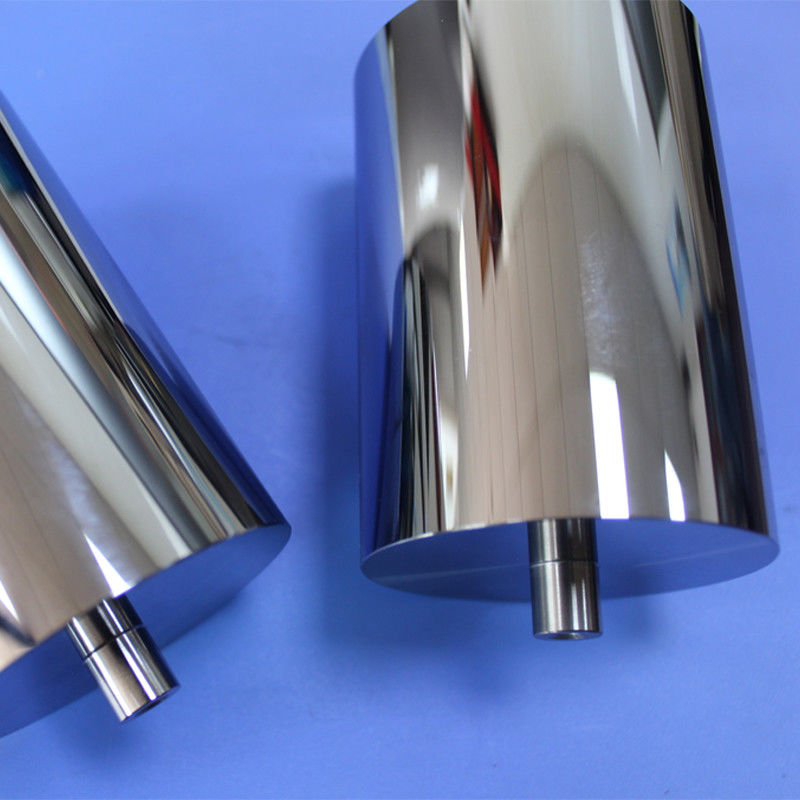

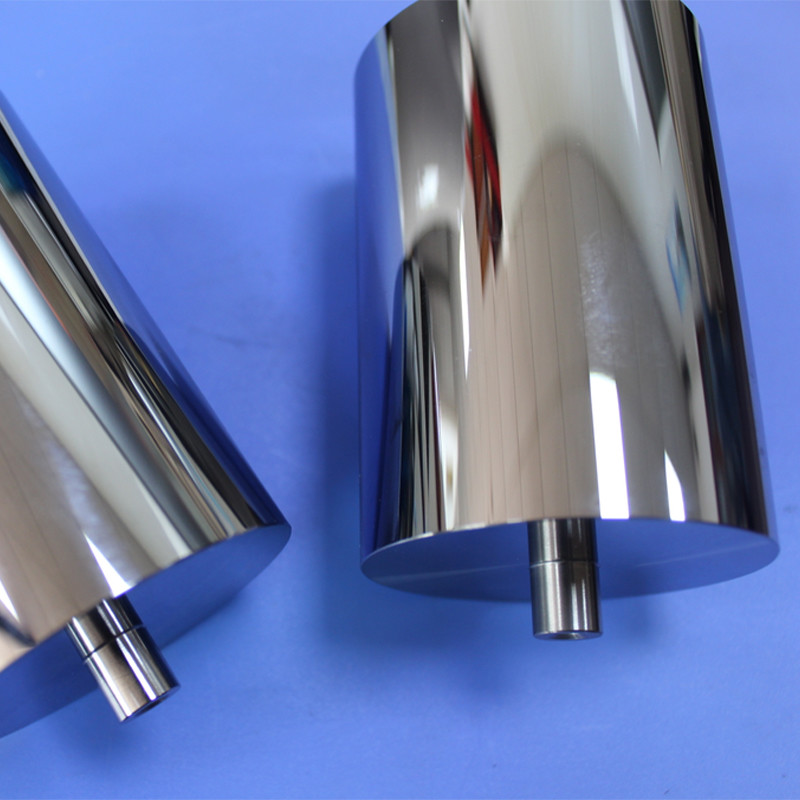

Customized High Precision Machined Tungsten Carbide Mill Rolls

| Product Specifications |

φ60*2-φ10-10*2-0.2*45°*105 |

| Standards Compliance |

Conforms to GB145-85 standards; B2 center holes meet standard requirements |

Features and Advantages

- Premium Material: Crafted from high-quality tungsten carbide and hard alloy, ensuring exceptional wear resistance and corrosion resistance under high strength and pressure.

- Precision Machining: The mill rolls undergo precision machining processes, achieving a smooth surface with a roughness of Ra0.1, showcasing a metallic luster to enhance efficient rolling and prolong lifespan.

- Strict Dimensional Control: Manufactured strictly according to specifications, ensuring perfect compatibility within rolling mills for improved rolling efficiency.

- Adheres to Tolerance Standards: Roller length of 85mm meets tolerance requirements, ensuring product stability and reliability.

- Excellent Verticality and Cylindricity: Roller verticality controlled within 0.01, and cylindricity requirement at only 0.004, ensuring stable and precise operation during rolling.

Application Field

Suitable for various rolling mills, particularly in environments involving continuous plastic deformation of metals.

Use Cases

Widely used in metal processing, rolling mills, and other industries to ensure product quality and production efficiency.

Usage Notes

Proper installation and maintenance, as per the operating manual, are essential before use to ensure prolonged and efficient operation of the product.

Tungsten Carbide Processing

We specialize in the production and processing of tungsten alloy products including tungsten alloy, tungsten parts, and custom tungsten processing.

Tungsten is a metal element with an atomic number of 74 and atomic weight of 183.84. It features steel gray or silver white appearance, high hardness, high melting point, and no air erosion at normal temperature. Tungsten is primarily used to manufacture filaments, wear-resistant hard alloys, super hard dies, optical instruments, and chemical instruments.

As a refractory metal with the highest melting point, tungsten offers excellent high-temperature resistance and superior corrosion resistance to molten alkali metals and vapors.

Technical Parameters

We specialize in producing tungsten parts according to specific customer requirements, primarily used for high temperature resistance, medical shielding, and counterweight applications.

Frequently Asked Questions

Are you manufacturer or trading company?

We are manufacturer of tungsten carbide products.

Where is your factory located?

We are located in Zhuzhou city, Hunan province, approximately 2 hours driving from Changsha airport.

Is the price competitive?

UKO offers reliable products with competitive pricing.

Are the products high quality?

Yes. Raw materials are tested before bulk production, and we verify physical properties, shape, and tolerance to ensure qualified products before shipping.

How to place an order of tungsten carbide products?

1. Fill your Order List in our online Inquiry System (or directly contact our salesperson by E-mail/Skype/WhatsApp)

2. We provide feedback within 24 hours of receiving your message

How we can trust your company?

We support Alibaba trade insurance with 100% products quality protection, 100% on-time shipment protection, and 100% payment protection for your covered amount.

What's your delivery time?

Standard types with existing molds: 2 weeks after receiving advance payment

Non-standard types without existing molds: 4 to 6 weeks after receiving advance payment

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!