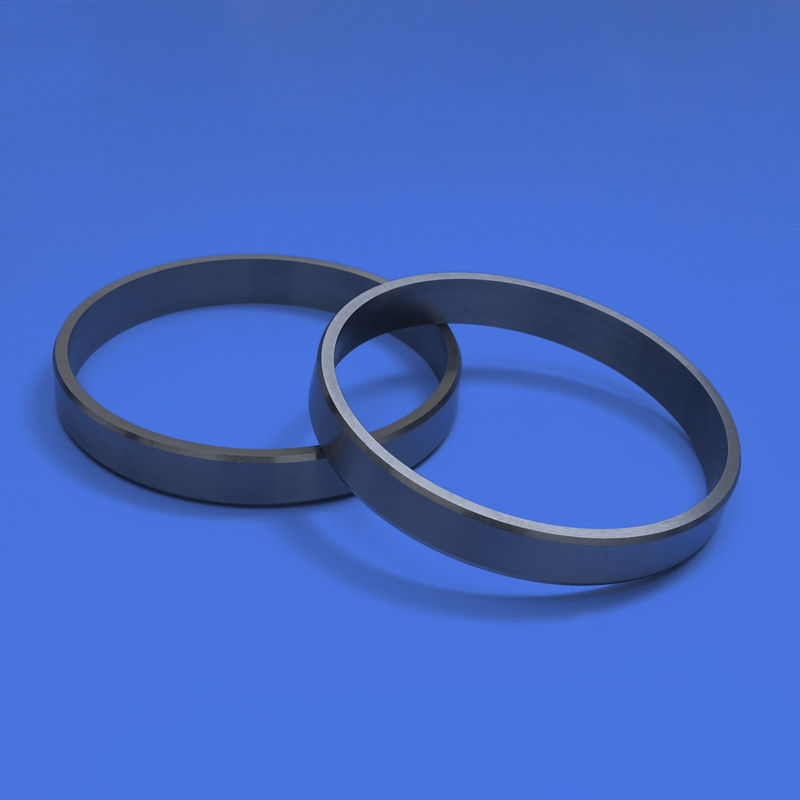

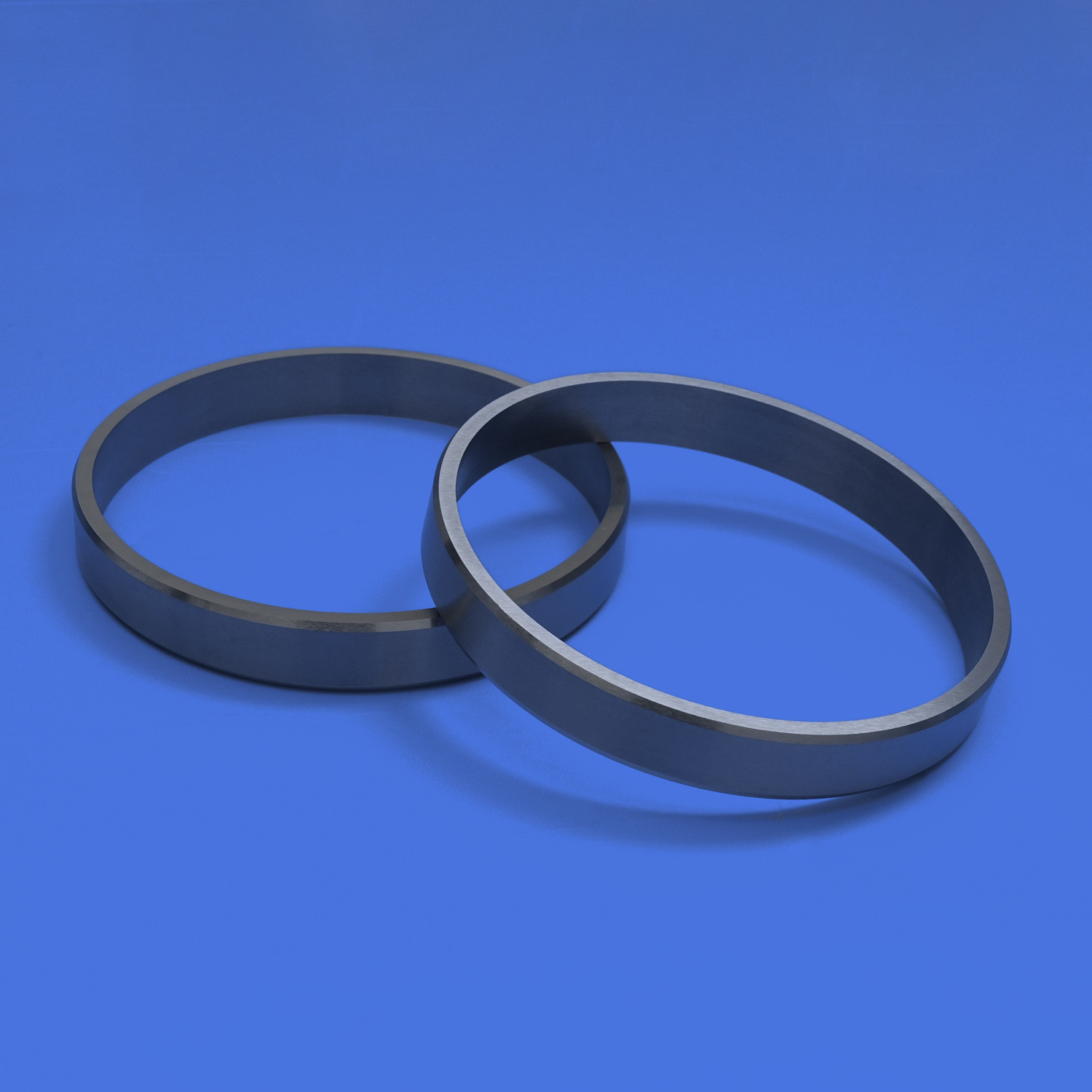

Machinery Spare Part Hard Metal Rings of Wolfram Carbide Material

Carbide seal rings are precision shaft seal devices designed for rotating machinery face seal applications, including centrifugal pumps, reactors, and compressors. These components prevent fluid leakage in equipment by creating a reliable seal between transmission shafts and machinery components.

In mechanical engineering, the fit between mating parts is critical. Without proper shaft sealing, equipment fluids can easily escape. Carbide seal rings provide either clearance fits for relative movement or tight interference fits for unified part action, ensuring optimal sealing performance.

Mechanical face seals consist of both stationary and rotating seal faces/rings. Tungsten carbide (wolfram carbide) is an ideal material for manufacturing these rings, offering exceptional performance in harsh and aggressive environments, particularly in oil and gas industry applications and acidic mechanical operations.

Custom Carbide Tool Manufacturing

We manufacture carbide tools according to customer specifications and drawings:

| Dimensions (Ø "A"-0,02 x Ø "B"H6 x 20,8 ±0,2 mm) |

Dimensions (Ø "A" -0,05 x Ø "B" H6 x 20,0 ±0,2 mm) |

| Ø 76,30 x Ø 68,00 x 20,8 | Ø 67,00 x Ø 55,00 x 20,0 |

| Ø 76,80 x Ø 68,00 x 20,8 | Ø 58,60 x Ø 46,60 x 22,0 |

| Ø 77,30 x Ø 68,00 x 20,8 | Ø 59,50 x Ø 47,50 x 22,0 |

| Ø 77,80 x Ø 68,00 x 20,8 | Ø 70,00 x Ø 58,00 x 22,0 |

| Ø 150,30 x Ø 140,00 x 20,8 | Ø 289,40 x Ø 277,40 x 20,0 |

| Ø 150,80 x Ø 140,00 x 20,8 | Ø 31,60 x Ø 19,60 x 20,0 |

| Ø 152,80 x Ø 140,00 x 20,8 | Ø 90,20 x Ø 78,20 x 20,0 |

| Ø 151,30 x Ø 140,00 x 20,8 | Ø 94,3 x Ø 82,30 x 20,0 |

| Ø 151,50 x Ø 140,00 x 20,8 | Ø 101,40 x Ø 89,40 x 20,0 |

| Ø 151,80 x Ø 140,00 x 20,8 | Ø 56,00 x Ø 44,00 x 20,0 |

| Ø 75,80 x Ø 68,00 x 20,8 | Ø 75,80 x Ø 63,80 x 20,0 |

| Ø 75,30 x Ø 68,00 x 20,8 | Ø 76,30 x Ø 64,30 x 20,0 |

| Ø 75,50 x Ø 68,00 x 20,8 | Ø 152,40 x Ø 140,40 x 20,0 |

| Ø 76,00 x Ø 68,00 x 20,8 | Ø 152,70 x Ø 140,70 x 20,0 |

| Ø 78,60 x Ø 68,00 x 20,8 | Ø 154,20 x Ø 142,20 x 20,0 |

| Ø 151,40 x Ø 140,00 x 20,8 | Ø 119,30 x Ø 107,30 x 20,0 |

Product Advantages

Cemented carbide wearing parts, also known as tungsten carbide (WC) parts, are premium components widely used in the hardware machinery industry due to their exceptional properties:

- High hardness and superior toughness

- Excellent high and low temperature wear resistance

- Minimal adhesion and low friction coefficient

- Superior corrosion resistance and acid/alkali protection

- High thermal conductivity and non-rusting properties

- Easy maintenance and long-lasting performance

With outstanding toughness, high temperature resistance, and exceptional wear resistance, our carbide seal rings deliver service life that is 10-50 times longer than standard metal components.

Sanxin Carbide Seal Rings Features:

- 100% virgin cemented carbide materials

- Fine-grain tungsten carbide construction

- Excellent wear, abrasion, and corrosion resistance

- High fracture strength and extreme hardness

- Extended service life and durability

- Multiple material grades available

- Competitive EXW factory pricing

- Comprehensive customization services

Packaging & Shipping

Due to their high density and compact size, our tungsten carbide processing products receive meticulous packaging to minimize transit damage risks. Cemented carbide components are secured in sturdy boxes and sealed to guarantee safe arrival at their destination.

We utilize premium packaging materials including bubble wrap, foam, bubble bags, cardboard, and other appropriate protective materials as needed.

We partner with reliable and efficient courier services, primarily offering express shipping options such as DHL, FedEx, and UPS for urgent orders.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!