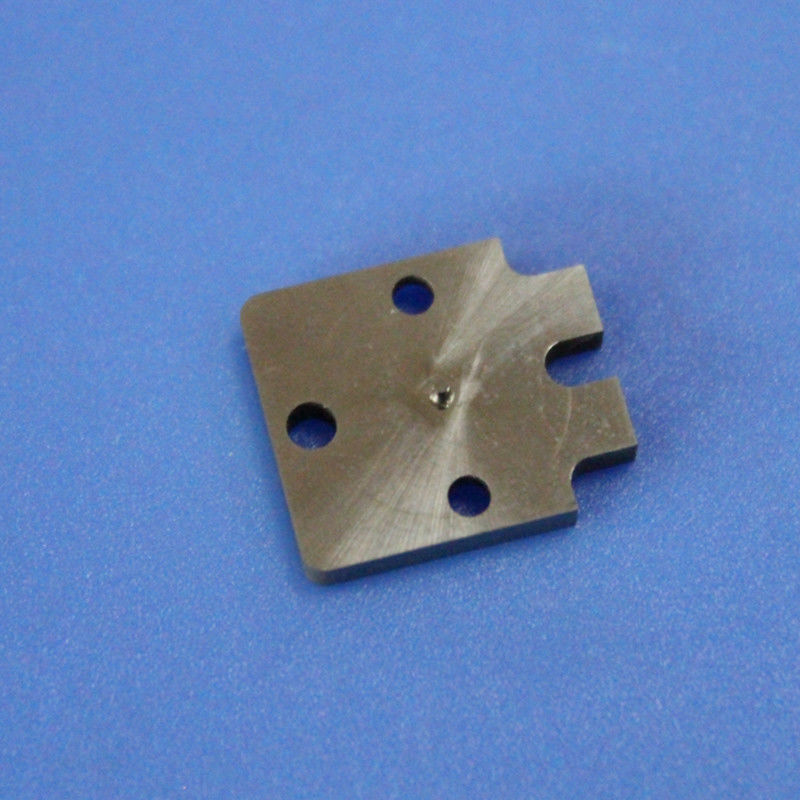

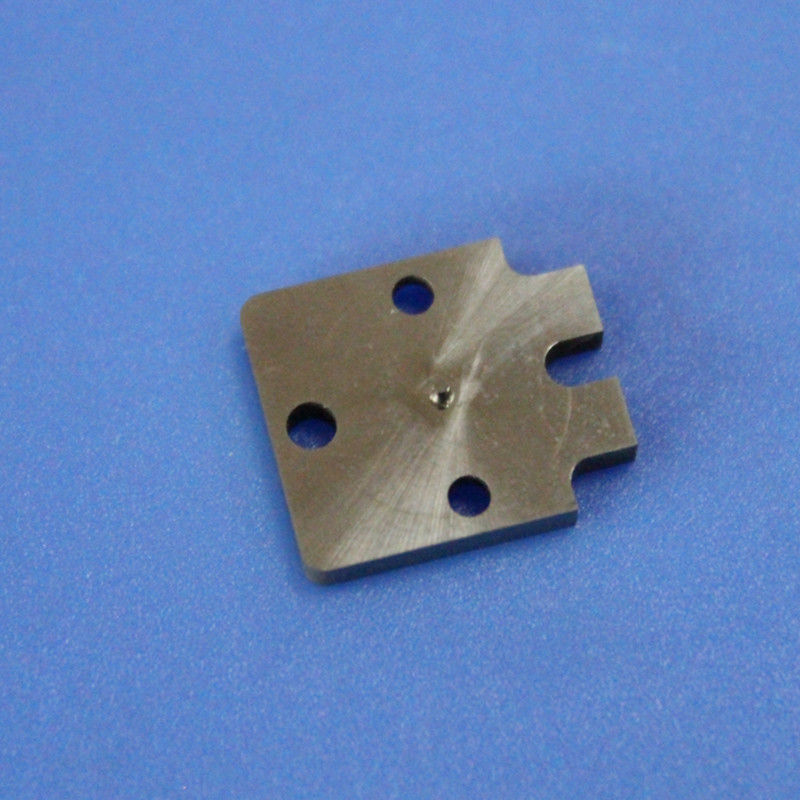

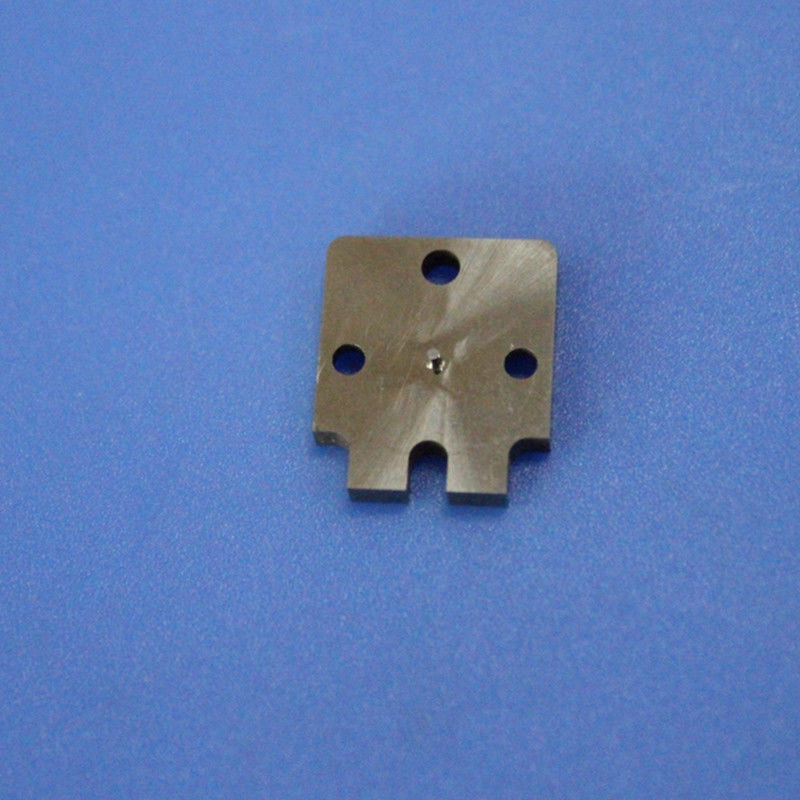

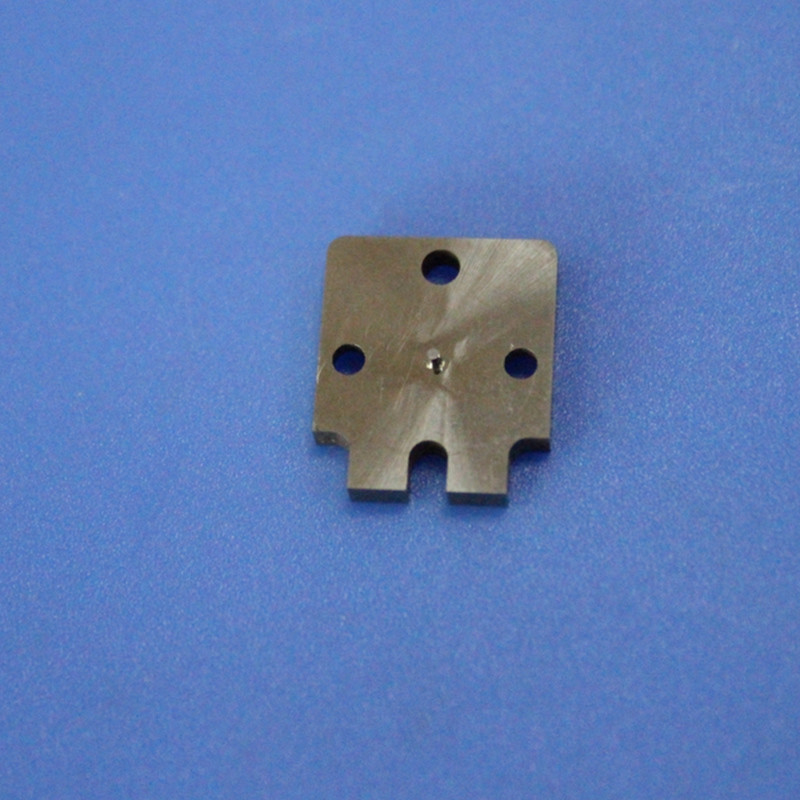

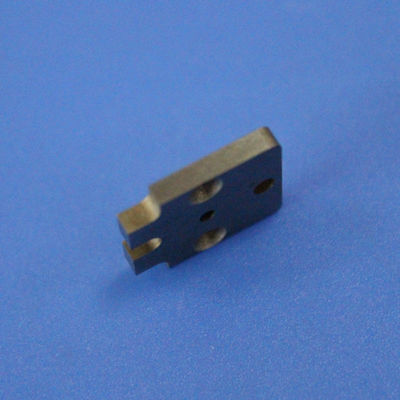

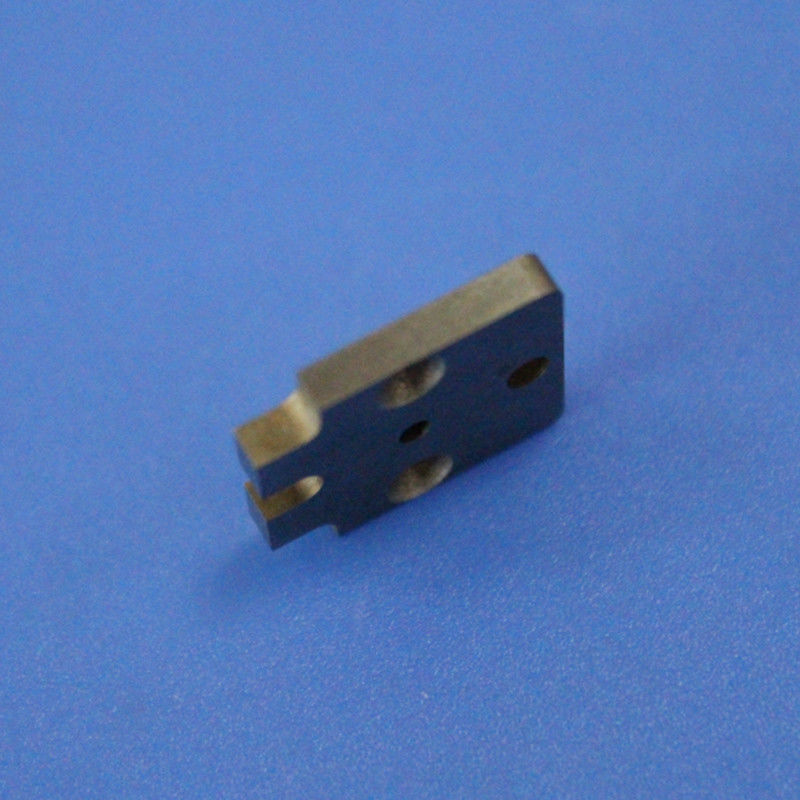

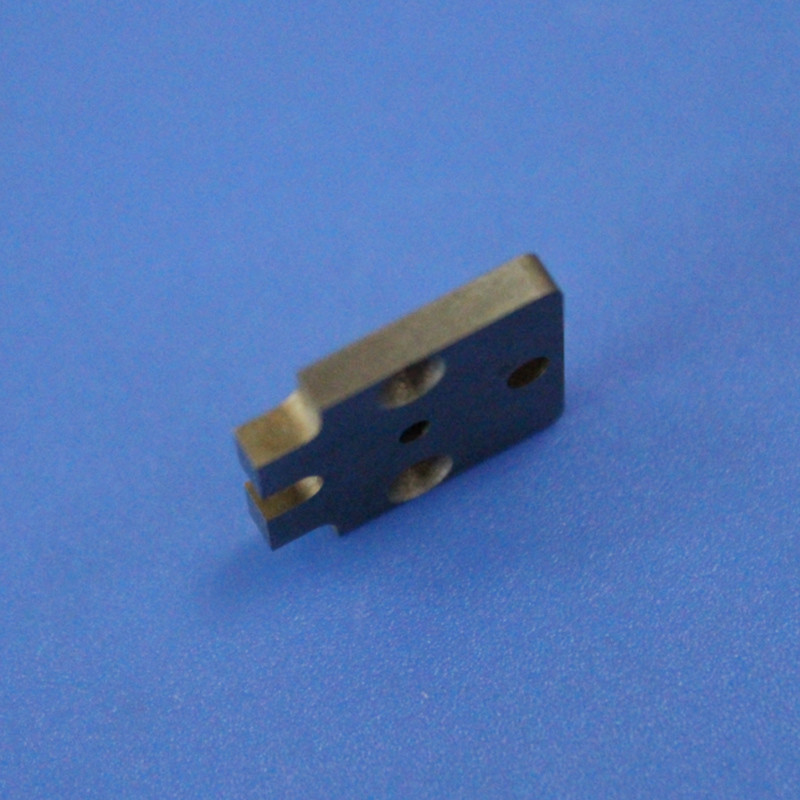

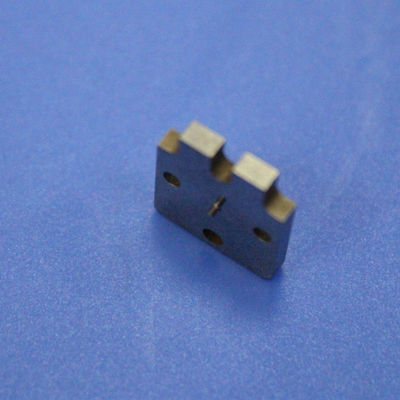

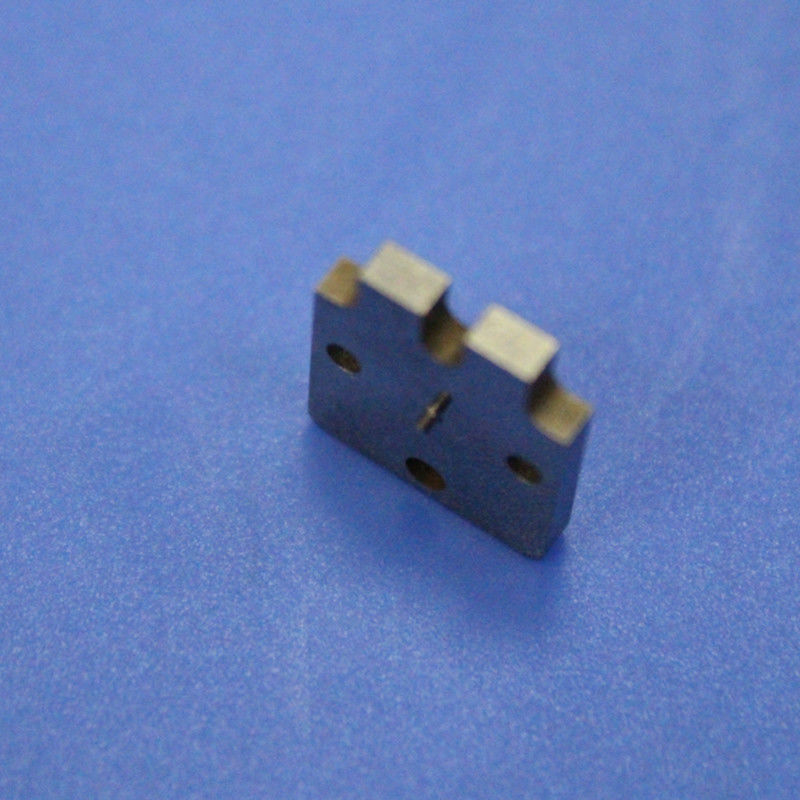

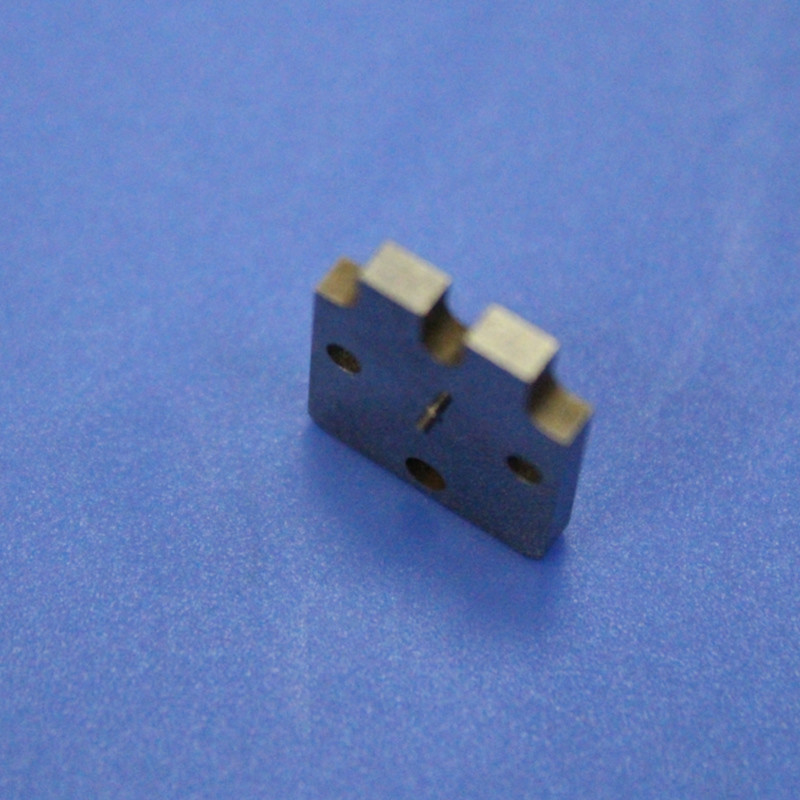

High-Quality Inkjet Equipment Tungsten Carbide Nozzle Tip Replacement

Our premium Tungsten Carbide Nozzle Tip is meticulously designed as a thin, plate-shaped component featuring specialized elliptical micro-holes. Crafted with precision, this nozzle tip ensures optimal performance for inkjet coding equipment, offering unparalleled precision and reliability.

Technical Specifications

| Center hole diameter |

0.04mm |

| Hardness |

HRA 91 |

| Key performance |

Wear-resistant and corrosion-resistant |

| Service Life |

Super long |

Leveraging the superior qualities of tungsten carbide, renowned for its exceptional hardness and durability, our nozzle tips excel in applications such as spraying, atomizing, and regulating fluid or gas flow. The unmatched wear resistance, corrosion resistance, and thermal stability make these nozzle tips ideal for rigorous industrial processes across manufacturing, automotive, aerospace, and chemical processing sectors.

Custom Processing & Precision

Engineered with high precision, our nozzle tips boast a remarkable tolerance of ±0.002mm and achieve a maximum hole roughness of Rz 0.2, ensuring smooth and consistent performance in demanding applications.

Industry Applications

Our versatile nozzle tips are designed for inkjet coding equipment across multiple industries:

- Packaging Industry: Ideal for coding and labeling products in food, beverages, pharmaceuticals, and cosmetics

- Pharmaceutical Industry: Efficiently mark batch numbers, expiration dates, and production dates on pharmaceutical packaging

- Food Industry: Print dates, batch codes, barcodes, and identifiers on food packaging

- Automotive Parts Industry: Perfect for serial numbers, batch codes, and specifications on automotive components

- Electronics Industry: Provides unique identification, serial numbers, and essential details on electronic devices

- Plastic Products Industry: Effectively label serial numbers and identifiers on plastic products

- Metal Products Industry: Mark identification, patterns, and serial numbers on metal items with precision

Inkjet coding equipment featuring our nozzle tips are indispensable for product identification, tracking, and ensuring production traceability across diverse industrial applications.

Inkjet Coding Equipment Capabilities

Coding Technology

Utilizes advanced inkjet technology to form high-resolution characters and patterns by precisely ejecting ink particles, ensuring clarity and versatility in marking.

Coding Capabilities

Offers flexible coding options including numbers, letters, symbols, barcodes, and QR codes to meet diverse product identification requirements.

High-Speed Operation

Designed for high-speed operation, enabling real-time coding on high-volume production lines while maintaining production efficiency.

User-Friendly Operation

Features intuitive interfaces and functions for easy setup and operation, allowing quick operator familiarization and accurate coding.

Durability and Reliability

Constructed with durable materials and robust designs to withstand industrial environments and ensure long-term stable operation.

Pollution Resistance

Exhibits excellent resistance to dust, humidity, and environmental contaminants, ensuring consistent marking quality and clarity.

Traceability and Quality Control

Provides essential tools for product traceability by marking unique codes that track origin, production batches, and relevant details.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!