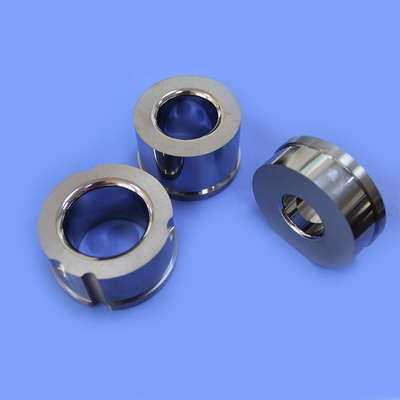

100% Original Tungsten Carbide Die Tube Drawing Dies

Premium tungsten carbide drawing dies with polished surface for superior performance in industrial applications.

Why Choose Our Tungsten Carbide Dies

Efficiency & Professionalism: Our experienced team delivers competitive pricing and high-quality products with rapid response times. All inquiries addressed within 24 hours.

Convenience & Safety: Comprehensive quality assurance with 100% product quality protection, on-time shipment guarantee, and secure payment protection.

Key Features

- High Hardness: Exceptional tungsten steel hardness provides superior wear resistance and extended tool lifespan

- Precision Manufacturing: High-precision engineering ensures consistent, accurate drawn products with dimensional stability

- Durability: Robust construction withstands high mechanical stress and repeated use without deformation

- Corrosion Resistance: Resistant to corrosion for reliable performance in demanding operating environments

- Temperature Stability: Maintains structural integrity and performance at elevated temperatures during continuous production

Main Applications

- Wire Drawing: Essential for producing wires with precise diameters and superior surface finish

- Tube Drawing: Used in seamless tube and pipe production for uniform thickness and smooth surfaces

- Rod Drawing: Ideal for manufacturing rods and bars with consistent diameter and surface quality

- Cable Manufacturing: Critical for cable and optical fiber production ensuring precise dimensions

- Metal Forming: Applied in various metal forming processes requiring high precision and durability

Product Introduction

Manufactured according to detailed specifications from Bohai Drilling Engineering Technology Research Institute, these tungsten carbide drilling tools serve as critical components for pulse restrictor applications. As industrial workhorses, cemented carbide drilling components deliver superior performance and efficiency compared to alternative materials.

Cemented carbide products provide essential performance support for oil exploration, drilling engineering, and geological mining operations. As a leading manufacturer in Zhuzhou's cemented carbide industrial chain, we leverage decades of expertise in hard alloy production.

Bohai Drilling Engineering Technology Research Institute specifications require cemented carbide components to exhibit acid and alkali resistance, corrosion resistance, high wear resistance, and excellent impact resistance for demanding drilling applications. Our company utilizes premium materials as the foundation for deep processing operations.

With four distinct product drawings, our manufacturing process from material selection to finished product delivery typically completes within one month. Each production phase undergoes strict quality control to meet cemented carbide product requirements. We specialize in custom production of non-standard hard alloy products, ensuring optimal value based on customer specifications and samples.

Technical Specifications

Engineered to Bohai Drilling Engineering Technology Research Institute specifications, these cemented carbide components feature acid and alkali resistance, corrosion resistance, high wear resistance, and excellent impact resistance for reliable drilling performance. Our manufacturing process begins with high-quality materials for superior deep processing results.

Manufacturing Advantages

Cemented carbide stands as the premier manufacturing tool for industrial applications. Leveraging Zhuzhou's 60-year heritage in cemented carbide military production technology and industrial infrastructure, we provide high-quality hard alloy wear-resistant parts and custom-shaped carbide products. Our material selection process ensures optimal performance based on specific customer requirements and application needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!