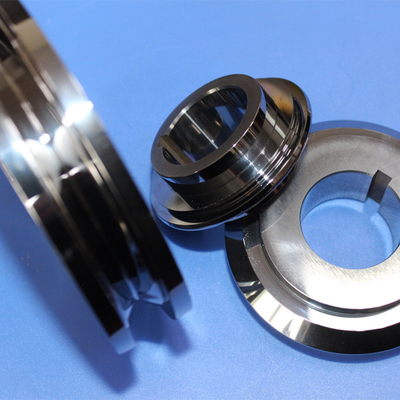

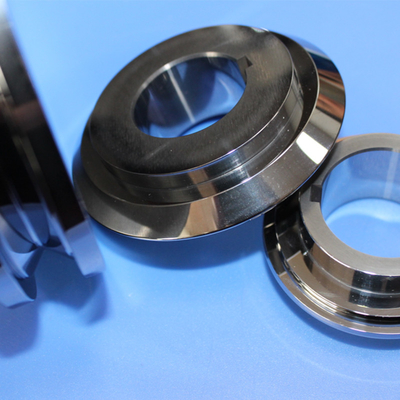

Professional Grade Tungsten Steel Punch and Die Wheel Tools

As industrial workhorses, cemented carbide components serve as the premier choice for high-quality wear parts due to their exceptional hardness, strength, and density. Our company specializes in manufacturing custom hard alloy non-standard shaped wear parts tailored to specific customer requirements.

Product Manufacturing Process

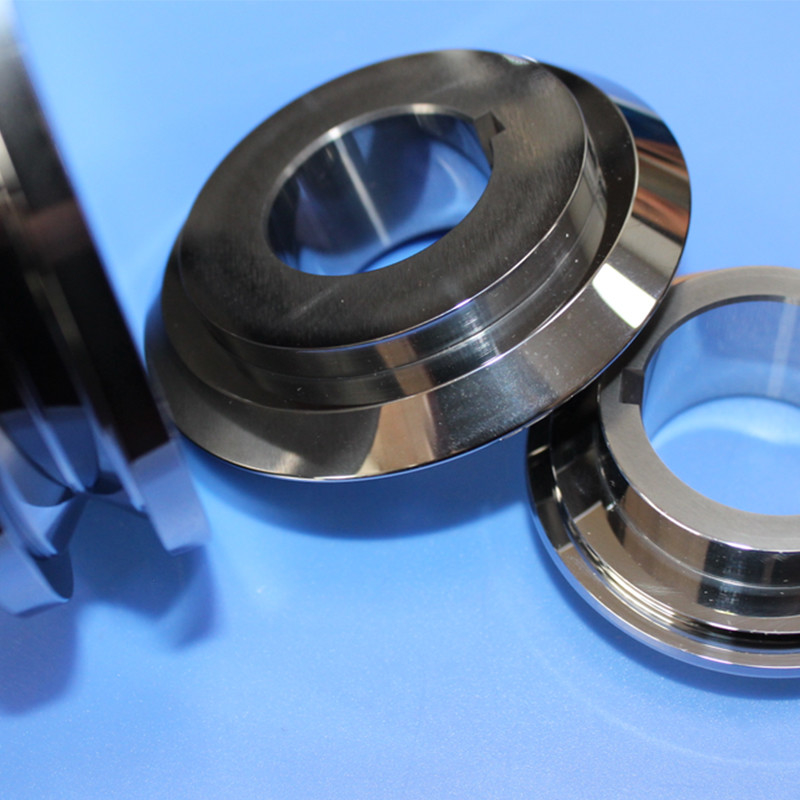

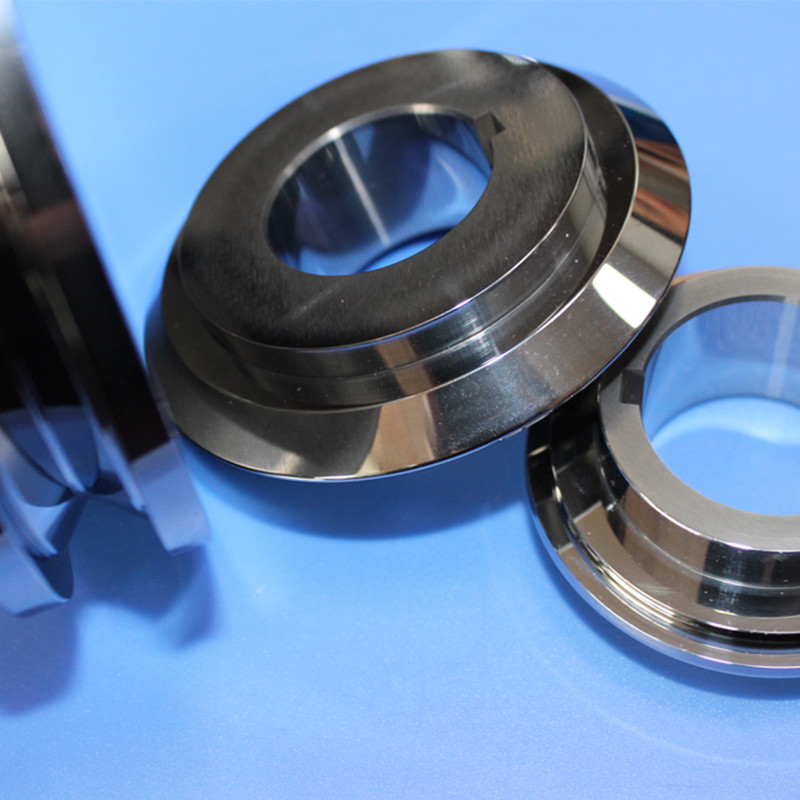

This upper indenter component is formed through pressing and sintering semi-finished blank carbide material. The internal thread is directly formed during the semi-finish production phase, with surface machining completed on precision machine tools. After fine grinding treatment and precise dimensional control processing, the component achieves flatness of 0.008 and perpendicularity of 0.02.

The hardness rating ranges between HRA92.5-93, meeting superior wear resistance requirements. Utilizing specialized cemented carbide production processes, the material is sintered at 1300°C using professional vacuum low-pressure sintering methods. This results in a compact metallographic structure free from sand holes and bubbles.

Technical Specifications

Size Specifications: Φ602-Φ54.32-Φ51.22-Φ48.4242.52-Φ4035.1

Surface Requirements: 2-3.5 size positions require groove-type mirror surface polishing (2R0.3-2R0.8)

Hardness: HRA92.5-93

Flatness: 0.008

Perpendicularity: 0.02

Material Advantages

100% virgin wolfram carbide materials

Fine-grain to ultra fine grain tungsten carbide available

Excellent wear, abrasion, and corrosion resistance

High fracture strength and hardness

Extended service life

Multiple cemented carbide material grades

Competitive EXW factory pricing

Customization services available

Application Benefits

This tungsten carbide wheel mechanical part serves as the crucial component in filling and sealing equipment, specifically designed for sealing filter canisters. The precise specifications and groove-type mirror surface polishing ensure smooth, reliable operation within filling and sealing systems.

Crafted from premium tungsten carbide, these components deliver outstanding wear resistance and corrosion resistance, maintaining excellent performance across various process environments.

Customer Service Commitment

- 24-hour response time for customer inquiries

- Effective and efficient communication throughout projects

- First-class quality control and after-sale services

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!