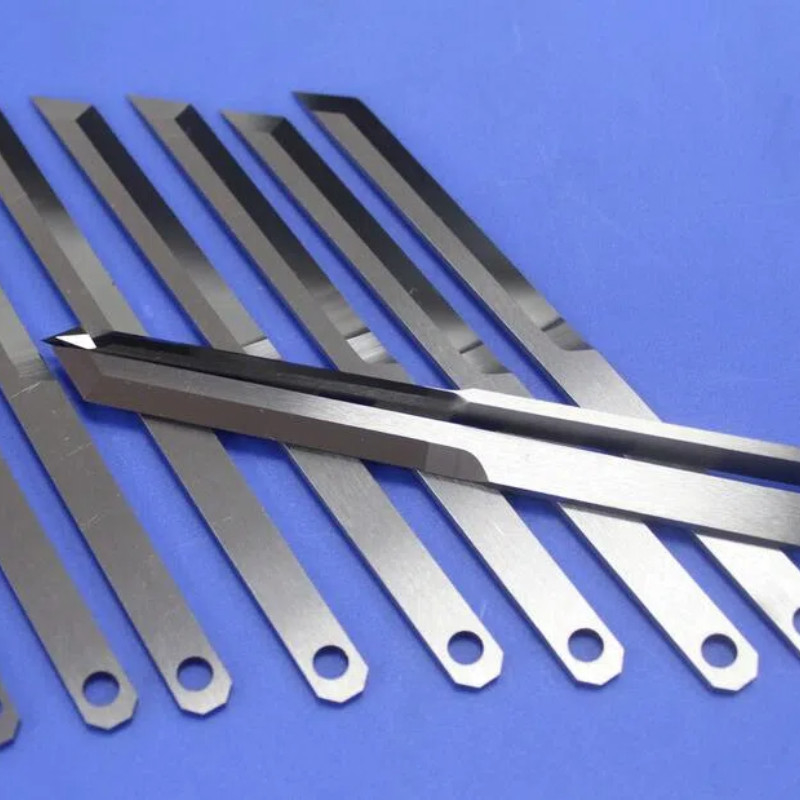

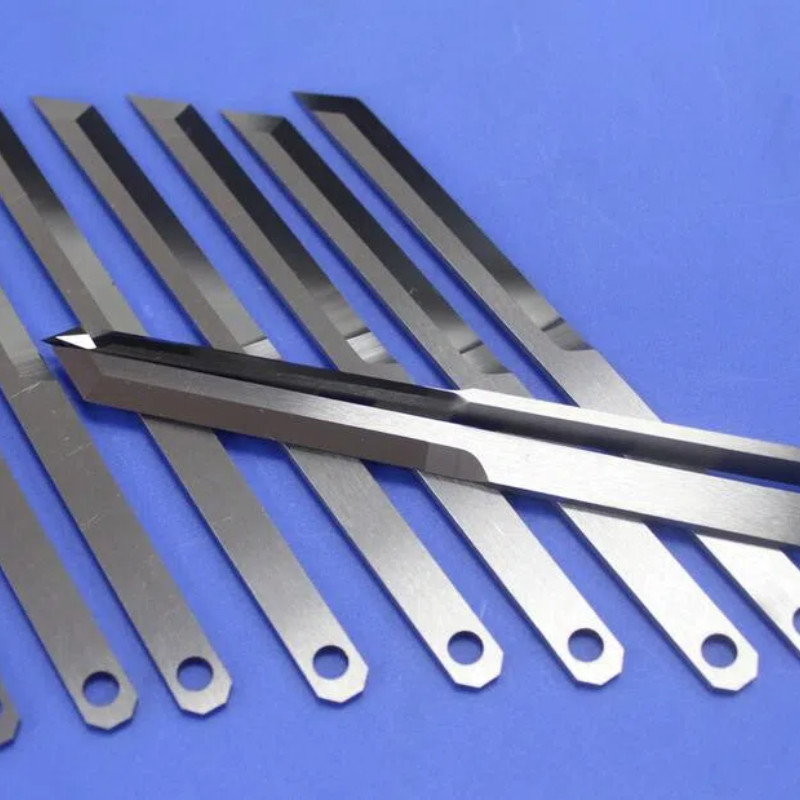

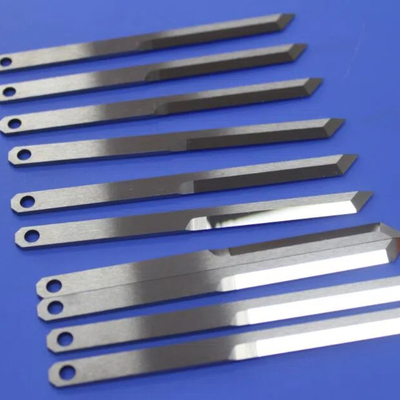

Tungsten Steel DC Wiring Cutting Blade Lathe Carbide Cutting Tools

A tungsten DC cutter, also known as a tungsten carbide DC cutter, is a specialized cutting tool designed to cut or sever direct current (DC) electrical circuits. It is typically used in electrical maintenance and repair tasks where the interruption or isolation of DC power is required.

Key Features & Specifications

Material: Tungsten DC cutters are made from tungsten carbide, a hard and durable material known for its exceptional wear resistance and strength. Tungsten carbide maintains sharpness and withstands high temperatures and abrasive wear.

Cutting Edge: Features a sharp cutting edge designed to efficiently and cleanly sever DC circuits. The precise cutting minimizes damage to circuits and ensures clean cuts with minimal burrs or debris.

Electrical Insulation: Designed with electrical insulation properties to ensure user safety during cutting operations. The insulation prevents electrical shocks and provides a barrier between the cutter and live electrical components.

Voltage and Current Rating: Engineered to handle specific voltage and current ratings, ensuring safe cutting and interruption of DC power circuits. Ratings are compatible with intended electrical systems.

Applications: Commonly used in electrical maintenance and repair tasks, including isolating electrical components, disconnecting circuits, or removing damaged sections of DC wiring. Ideal for safely cutting or interrupting DC power without damaging surrounding components.

Sanxin Carbide Product Features

| 100% virgin wolfram carbide materials |

Fine-grain, even ultra fine grain tungsten carbide available |

| Excellent wear, abrasion, corrosion resistance |

High fracture strength and high hardness |

| Longer service life |

Varied cemented carbide material grades |

| Competitive EXW factory price |

Customization service |

Packaging & Shipping

Tungsten Carbide Processing products are carefully packaged to minimize the risk of damage during transit. All products are securely boxed or wrapped with extra padding and bracing as necessary. We use only the highest quality packaging materials to ensure safe arrival and ship using reliable courier services. Express shipping is available for urgent orders.

About Our Company

Our company specializes in producing and manufacturing hard alloy insert pins for precision mold customers, particularly for electronic ceramic injection molds. These applications demand extremely high precision requirements, where perfect product consistency is the primary standard.

The tungsten carbide punching pins used in electronic ceramic precision molds are required in large quantities, with each insert pin maintaining excellent consistency. Our finishing process strictly controls each procedure to guarantee product consistency with tolerance requirements of +0.002 and finish requirements of 0.2, meeting the highest standards for electronic ceramic injection mold applications.

- National high-tech enterprise certification

- Processing high tolerance accuracy ±0.001mm

- Wear-resistant, heat-resistant, and anti-corrosion

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!