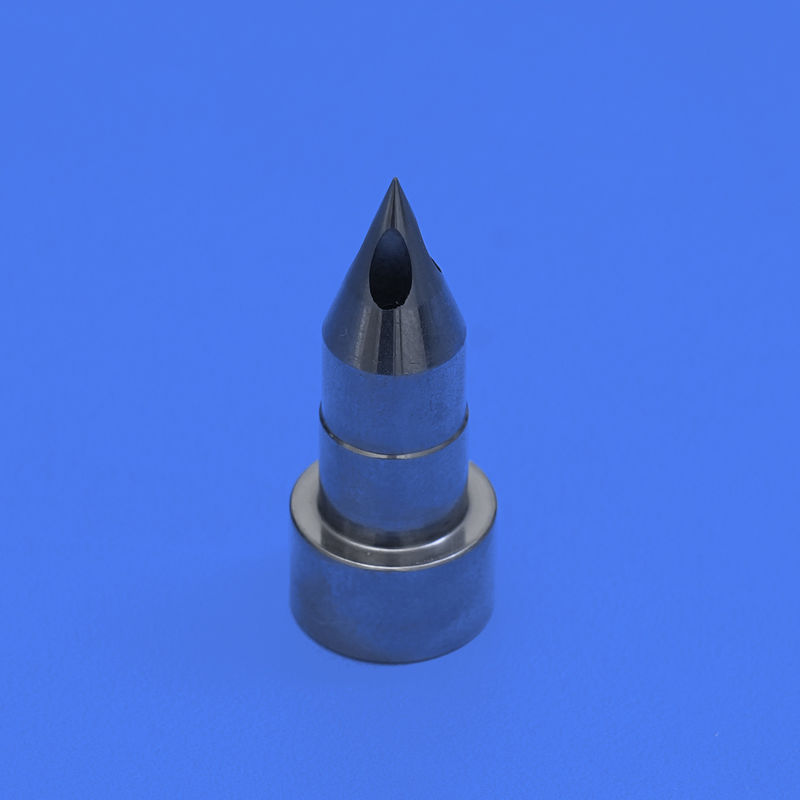

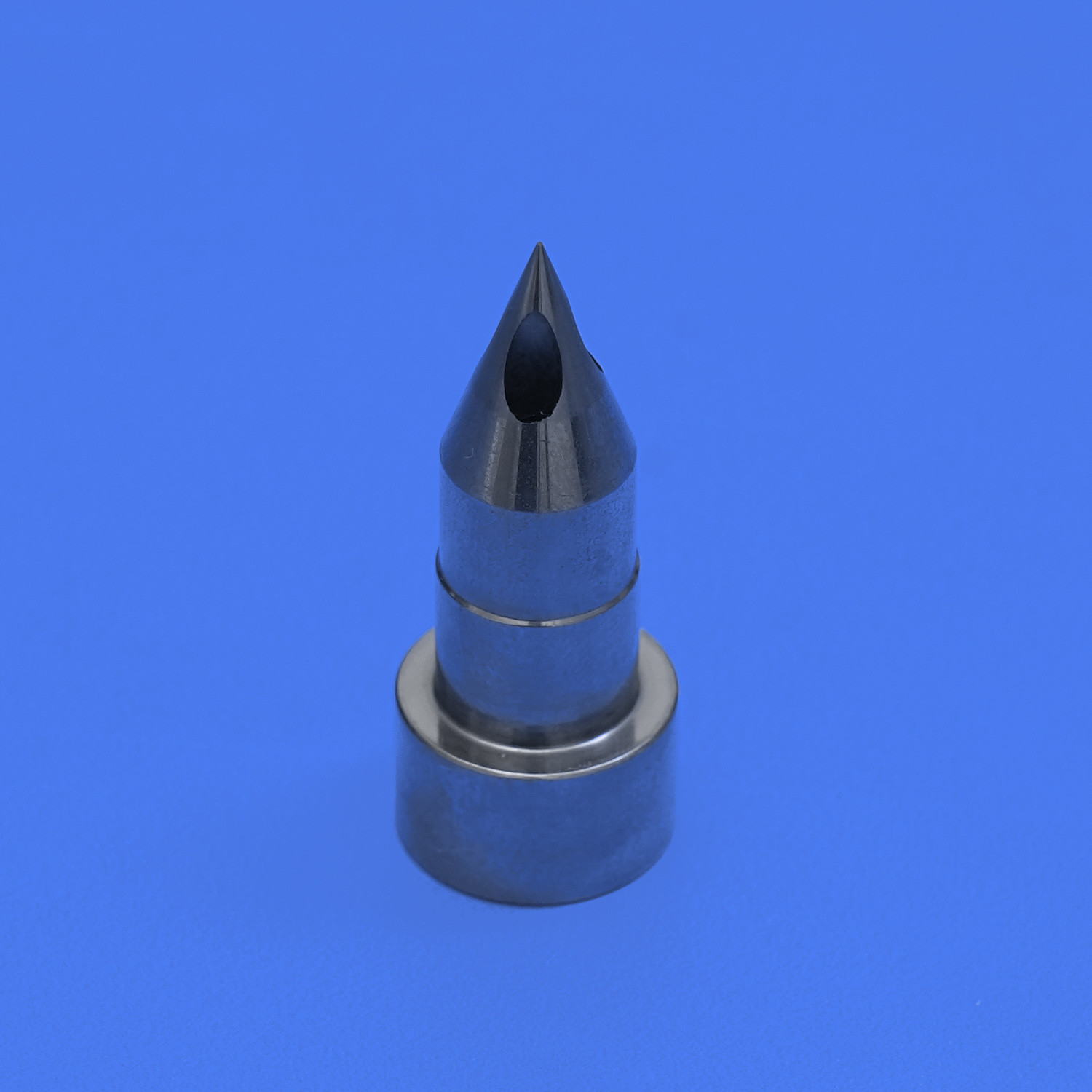

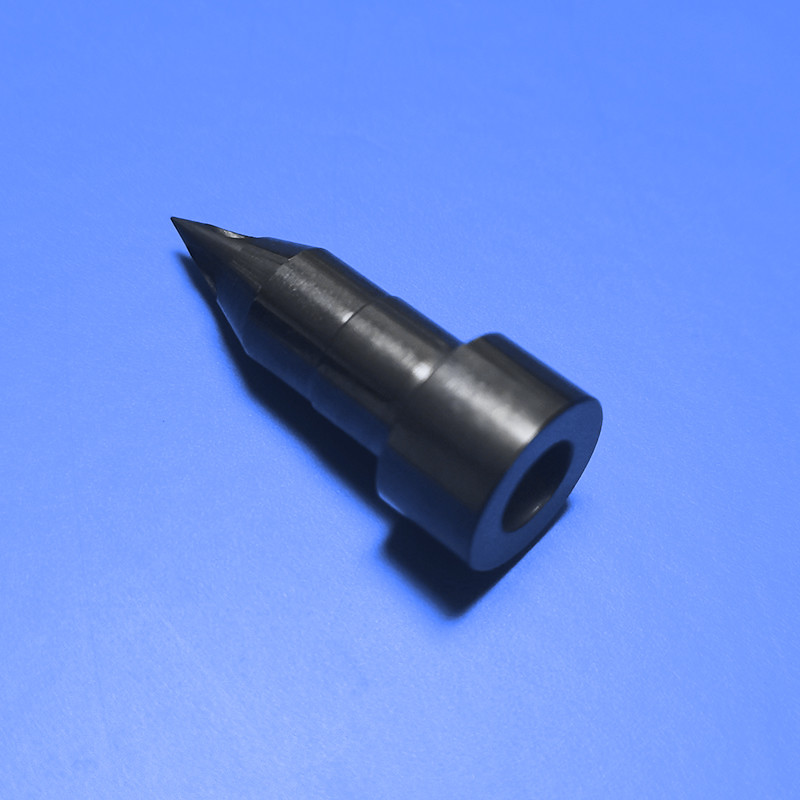

Customized High Quality Three-hole Hot Runner Cemented Carbide Nozzle

This tungsten carbide three-hole hot runner nozzle is a critical injection molding component engineered for exceptional wear resistance and high-temperature stability. Manufactured from premium tungsten carbide material through precision machining and specialized treatments, it delivers outstanding performance in demanding high-temperature, high-pressure injection molding environments, enabling efficient and precise thermal flow control for plastic product manufacturing.

The customized three-hole hot runner cemented carbide nozzle provides precise control, superior durability, and compatibility with various materials, making it essential for injection molding processes. It ensures efficient production, consistent part quality, and reduced maintenance downtime.

Product Features

- Outstanding Wear Resistance: Tungsten carbide material provides exceptional wear resistance, ensuring stable long-term performance throughout the injection molding process.

- High-Temperature Stability: Designed for high-temperature environments, the nozzle maintains consistent performance under extreme conditions, ensuring uniform plastic material flow.

- Precision Machining: Advanced machining processes create accurate dimensions and shapes, delivering precise injection molding control for plastic products.

- Reliable Performance: Combining high wear resistance and thermal stability, the nozzle delivers dependable performance in complex injection molding operations, enhancing production efficiency.

Key Benefits

| Precise and Uniform Injection |

The three-hole configuration enables controlled, balanced injection of molten plastic material, resulting in uniform mold cavity filling and consistent part quality with reduced defects. |

| High Wear Resistance |

Cemented carbide's exceptional wear resistance extends nozzle lifespan and minimizes replacement frequency, particularly beneficial in high-volume production environments. |

| Thermal Stability |

The cemented carbide material maintains excellent thermal stability, withstanding injection molding temperatures without deformation or performance degradation. |

| Material Compatibility |

Compatible with a wide range of plastic materials including commodity and engineering-grade resins, maintaining performance even with corrosive materials over time. |

Applications

Tungsten carbide three-hole hot runner nozzles are extensively used in injection molding applications requiring high product quality and precise control. Whether manufacturing automotive components or electronic product injection molding, this product delivers efficient, stable thermal flow control to ensure high-quality plastic product production.

Function

A hot runner cemented carbide nozzle is a specialized injection molding component designed to deliver molten plastic material to the mold cavity with precision and control. The three-hole configuration provides multiple injection points for efficient, uniform mold filling.

Material

Constructed from cemented carbide, a composite material consisting of tungsten carbide particles and a metallic binder (typically cobalt). This material combination provides high hardness, exceptional wear resistance, and thermal stability ideal for demanding injection molding applications.

Hot Runner System

The hot runner system comprises components that maintain molten plastic at controlled temperatures until it reaches the nozzle, including heaters, temperature controllers, and manifolds. The three-hole nozzle is an integral system component responsible for precise molten plastic delivery to the mold.

Customization

The three-hole hot runner cemented carbide nozzle can be customized to meet specific application requirements. Customization options include nozzle size, hole diameter, nozzle length, and nozzle tip design, all tailored to specific injection molding applications and desired outcomes.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!