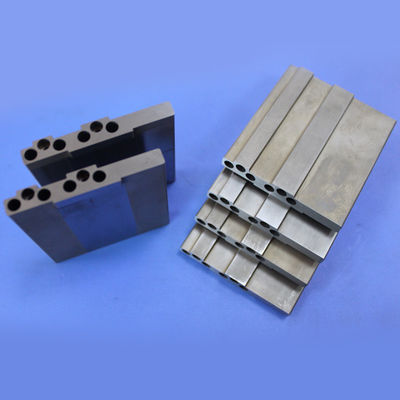

High Precision Tungsten Carbide Punch Die for Battery Case Stamping

Specialized tungsten carbide punch pins engineered for precision stamping applications in battery manufacturing, offering exceptional durability and performance in demanding industrial environments.

Key Features and Applications

| 1 |

Tungsten carbide punch pins for hard alloy processing |

| 2 |

Precision custom production of tungsten carbide punch pins for Fudi battery negative electrode stamping |

| 3 |

Specifically designed for punching process of C112F negative electrode lead-out strip in stamping dies |

High wear resistance and extended service life are essential for precision-stamped products, particularly in complex stamping dies including progressive, combination, and multi-station types. Tungsten carbide punch pins deliver superior performance in these demanding applications, offering unmatched hardness, strength, and wear resistance for high-quality tooling in stamping operations.

Carbide Punch Die Technical Specifications

Industry Background

The continuous advancement of power battery technology drives innovation in the new energy vehicle sector. These precision punch pins are custom-engineered for Fudi Battery Stamping Die Factory, a key manufacturing partner in the industry.

Fudi Battery Co., Ltd., a strategic division of BYD, originated as BYD Lithium Battery Co., Ltd. in 1998. With over two decades of experience in the secondary rechargeable battery market, Fudi Battery maintains comprehensive expertise across the entire battery industry value chain. Their product portfolio includes 3C consumer batteries, power batteries, energy storage systems, and automotive battery components including BMS, relays, capacitors, and fuses. Fudi Battery provides integrated service solutions to major global clients, supported by more than 20 years of research and development excellence spanning from mineral resource development to battery recycling and cascade utilization.

Manufacturing Excellence

Zhuzhou Sanxin Cemented Carbide Manufacturing Co., Ltd specializes in the research, development, processing, sales, and after-sales service of cemented carbide materials. Sanxin provides superior tungsten carbide OEM services and innovative technical solutions, supported by a dedicated engineering team that ensures the production of premium-quality tungsten carbide products.

Our core operational principles emphasize:

- Quality and customer first approach

- Sample availability for evaluation

- Punctual delivery commitments

- Mutually beneficial partnerships

- Focus on innovation and technology

- Service-driven value creation

At Sanxin, we are committed to delivering exceptional carbide value through superior materials and manufacturing expertise.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!