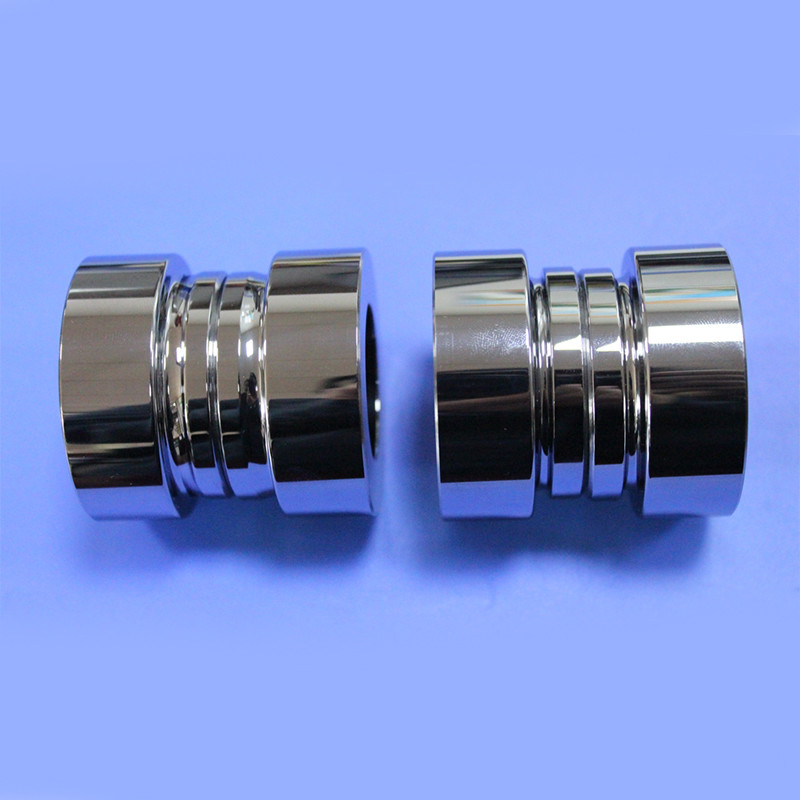

Customized High-Hardness Tungsten Carbide Rollers for Sealing Machines

Precision-engineered tungsten carbide rollers specifically designed for 1-3 and 2-4 processes in sealing machines, delivering exceptional performance and reliability in demanding industrial applications.

Key Features

- Precision-machined tungsten carbide rollers for 1-3 and 2-4 sealing machine processes

- Accurate dimensions ensure outstanding performance during sealing operations

- Superior hardness and wear resistance for extended service life

Product Advantages

- Replacement of Original Material: Direct substitute for Japanese SKD-11 (DC53) white steel metal rollers

- Aesthetic Appeal: Precision machining creates metallic luster while maintaining superior performance characteristics

Dimension Specifications

- Sealing Machine Tungsten Carbide Roller 1-3 Path: φ49*φ42*φ25.4*R0.5-R0.9-R2.0-R1.0-2.9*25.4

- Sealing Machine Tungsten Carbide Roller 2-4 Path: φ49*φ42*φ28.575*R0.5-R8.35-R1.35-R1.0-4.4*25.4

Critical Working Part

The main working component is the R-size, requiring R-arc to achieve mirror-like smoothness, ensuring precise dimensions and smooth coordination in sealing operations.

Material Properties

| Property |

Range |

| Grain Size (μm) |

0.4-2.0 |

| Cobalt Content (% Co) |

6-20 |

| Density (g/cm³) |

13.96-14.85 |

| Hardness (HRA) |

86-93 |

| Flexural Strength (MPa) |

3200-4500 |

| Young's Modulus (GPa) |

570-620 |

Customization Service

We provide comprehensive customized tungsten carbide roller processing to meet various sealing machine mechanical requirements. Our expertise ensures customer specifications are precisely met with guaranteed product quality.

Packing and Shipping

All tungsten carbide products are packaged according to the highest quality standards. Products are bubble-wrapped and sealed in heavy-duty cardboard or wooden boxes for maximum protection. International shipments include waterproof plastic film wrapping. All packages feature barcodes and customer tracking numbers for easy monitoring.

We utilize air freight, ground transportation, and ocean freight services. All orders include full insurance and tracking to ensure safe, timely delivery with competitive rates and excellent customer service.

Company Profile

Zhuzhou Sanxin Cemented Carbide Manufacturing Co., Ltd. specializes in cemented carbide products including nozzles, bushings & sleeves, sealing rings, molds, inserts, mill rollers, and customized components.

Cemented carbide is a composite hard alloy material consisting of refractory metal bonded together by a metallic binder through powder metallurgy. It offers exceptional properties including high hardness, wear resistance, strength, and toughness, making it ideal for harsh industrial environments.

Tungsten carbide and tungsten alloy are widely recognized as the premier materials in cemented carbide applications, also known as metal ceramic.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!