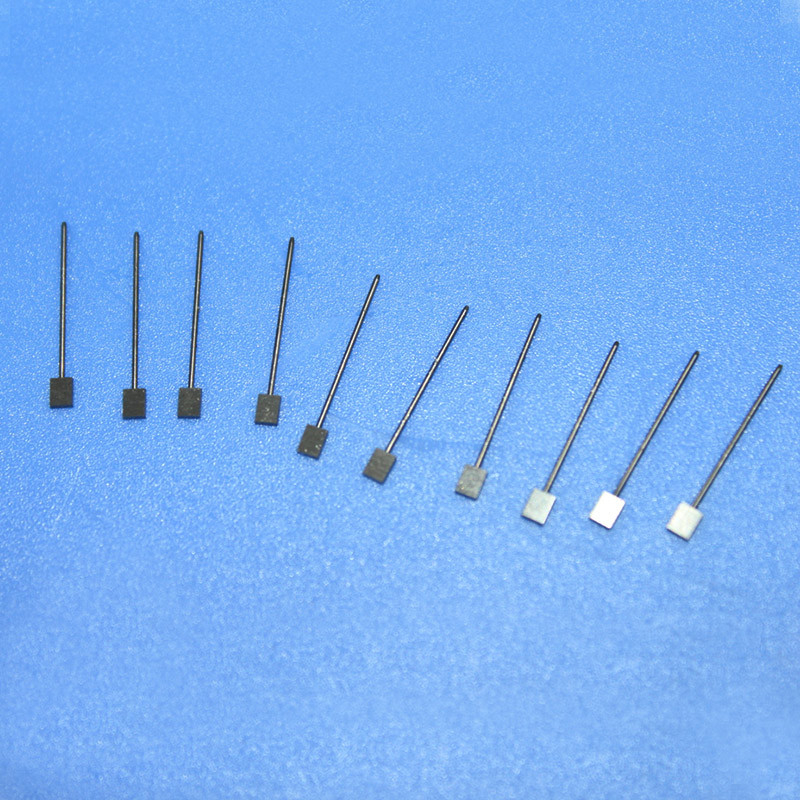

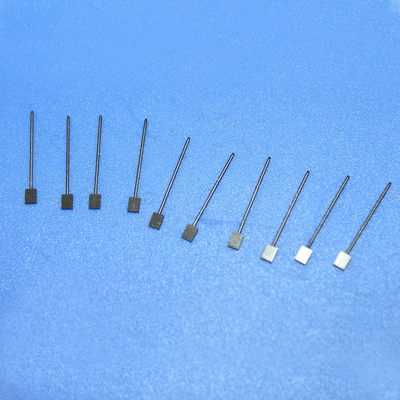

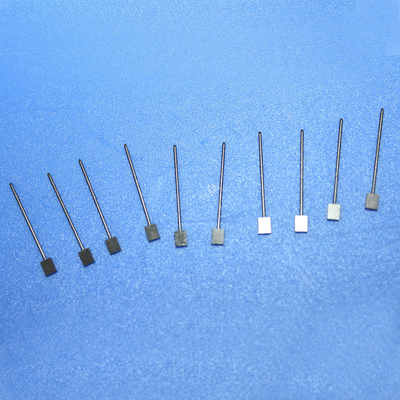

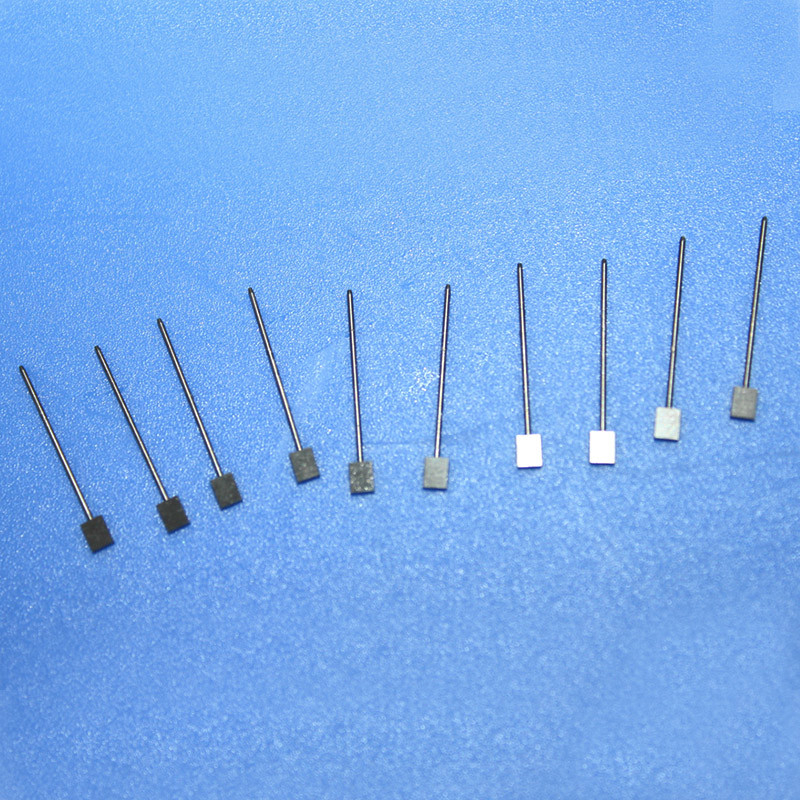

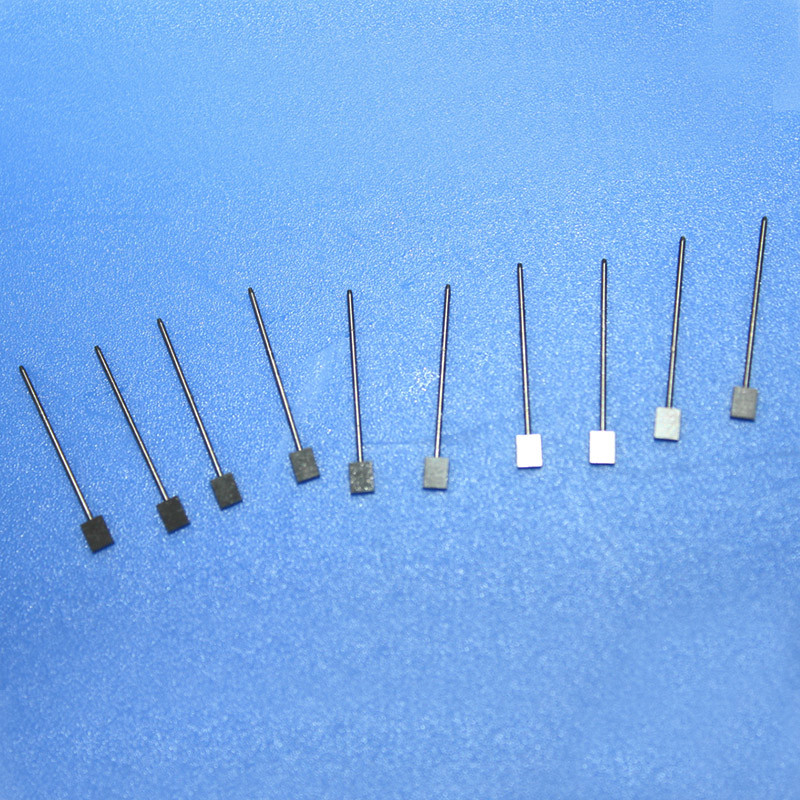

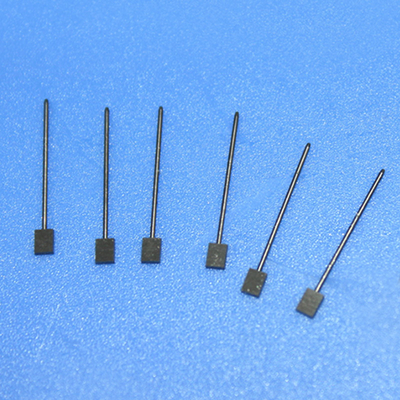

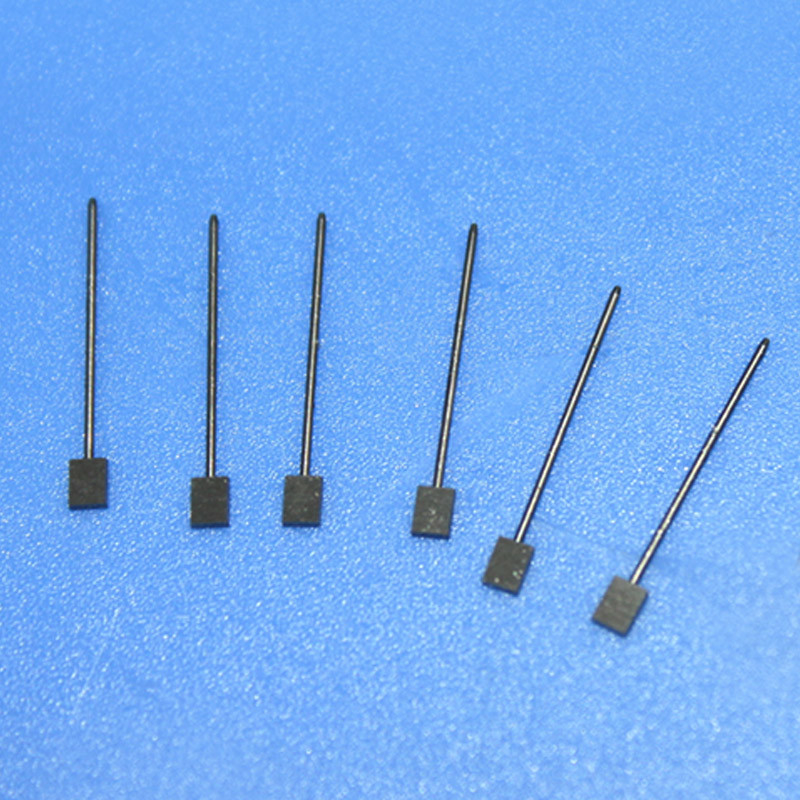

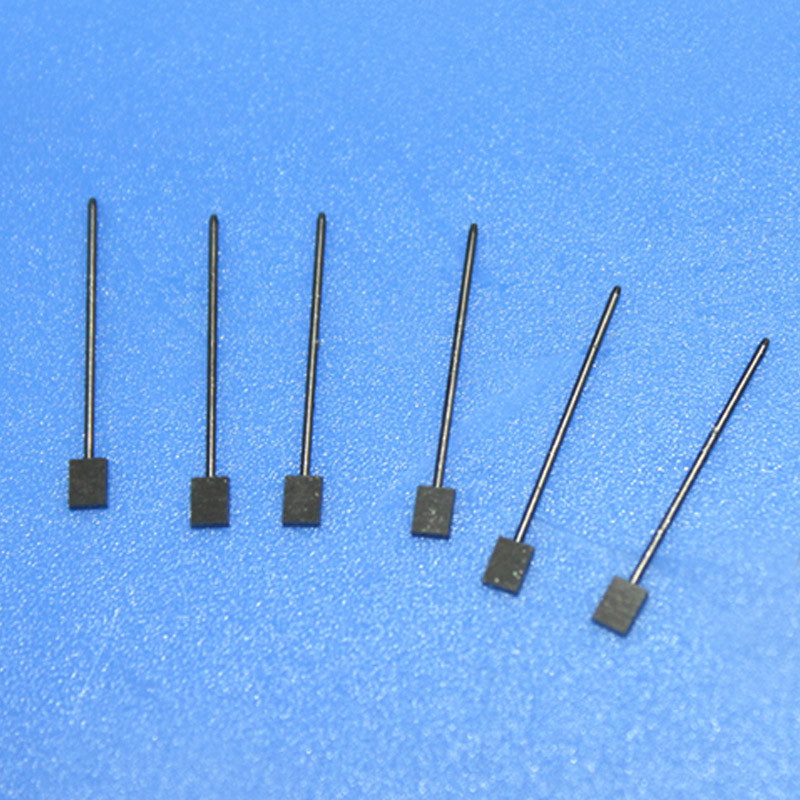

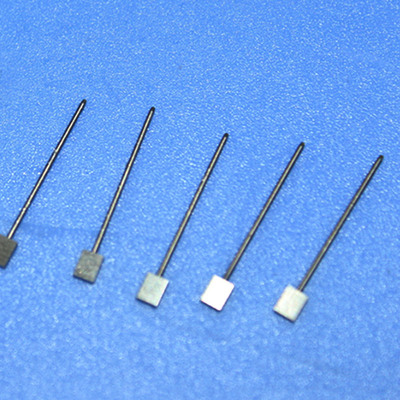

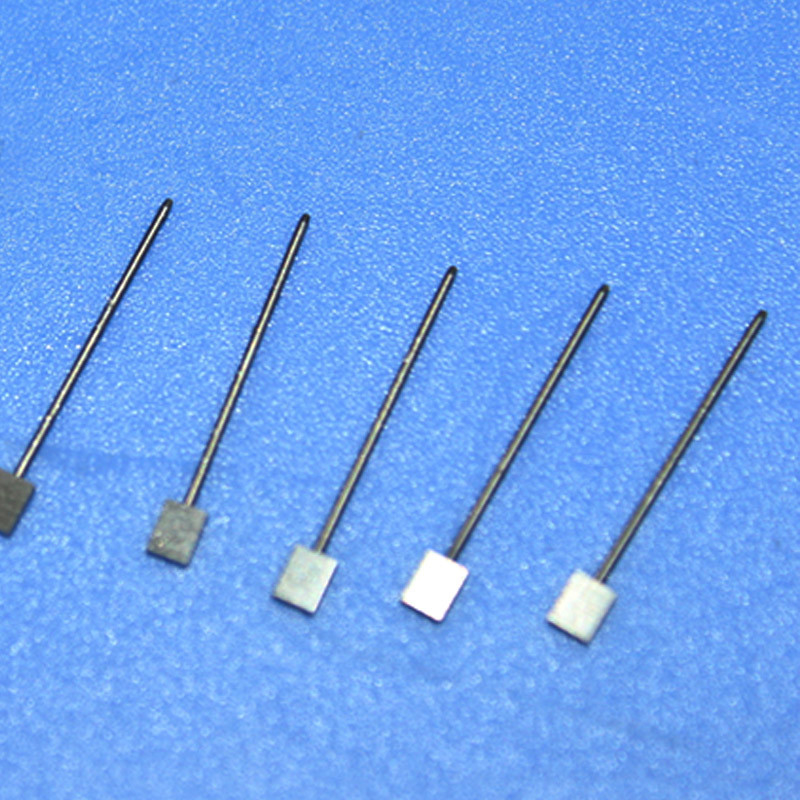

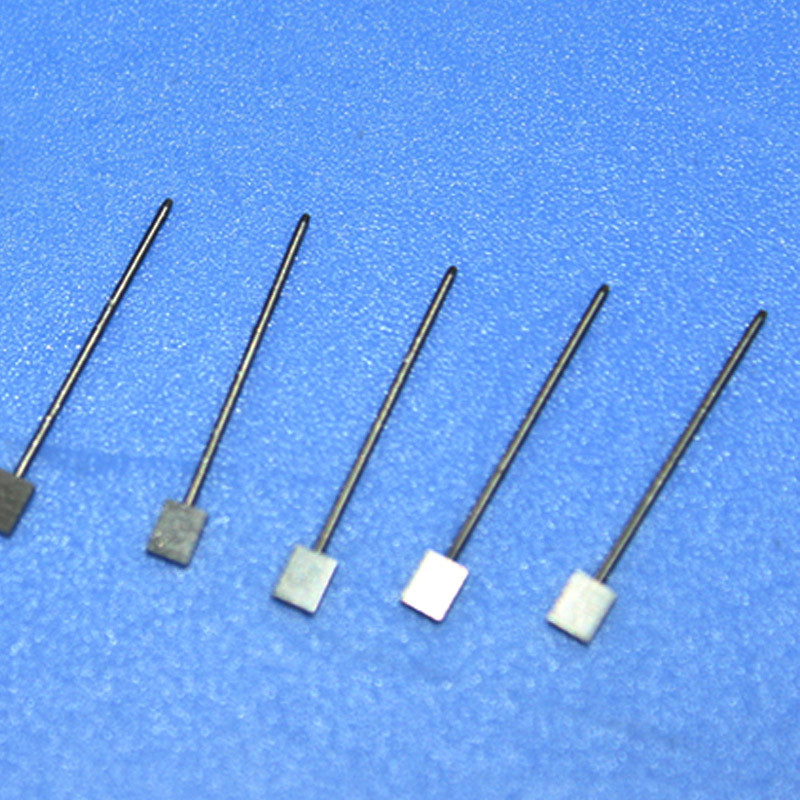

0.502 Super Hard Material Tungsten Carbide Insert Pins for Moving Molds

Moving molds, also known as sliding molds or dynamic molds, are essential components in various manufacturing processes, particularly in the plastics and metalworking industries. Tungsten carbide insert pins for moving molds are specialized components used in molding applications where precise movement and wear resistance are crucial.

Key Features

1

Material Properties: Tungsten carbide insert pins are chosen for their exceptional hardness, wear resistance, and strength, making them ideal for withstanding the high pressures and repetitive motion cycles in moving mold applications.

2

Precision Machining: These insert pins are manufactured with high precision to tight tolerances, ensuring they fit accurately within the mold assembly and provide smooth and reliable movement during the molding process.

3

Interchangeability: Tungsten carbide insert pins are often designed to be interchangeable within the mold, allowing for easy replacement and maintenance without requiring significant downtime.

4

Low Friction: The low coefficient of friction of tungsten carbide reduces wear on the pins and ensures smooth movement within the mold, contributing to the longevity of the pins and the quality of the molded parts.

5

Custom Designs: These insert pins can be customized in terms of size, shape, and configuration to meet the specific requirements of the moving mold application, allowing for tailored solutions for different molding processes.

6

Wear Resistance: Tungsten carbide insert pins exhibit exceptional wear resistance, ensuring extended service life and minimizing the need for frequent replacements, leading to cost savings and improved operational efficiency.

7

Corrosion Resistance: Tungsten carbide is highly resistant to corrosion, ensuring the longevity and performance of the insert pins even in harsh molding environments where exposure to moisture or chemicals is a concern.

Operational Benefits

Precision Movement: These insert pins facilitate accurate and consistent movement of mold components, ensuring the production of high-quality and uniform molded parts.

Durability: Tungsten carbide insert pins offer long-lasting performance and durability, reducing maintenance requirements and downtime in manufacturing operations.

Improved Efficiency: By providing smooth and reliable movement within the mold, these insert pins contribute to increased efficiency and productivity in molding processes.

Quality Assurance: The use of tungsten carbide insert pins helps maintain tight tolerances and ensures the integrity of the molded parts, enhancing overall quality control processes.

Tungsten carbide insert pins specifically designed for moving molds are critical components that play a key role in ensuring the smooth operation and precision of molding processes, ultimately leading to the production of high-quality and consistent molded parts.

Material Composition

Tungsten carbide is a major component of cemented carbide materials. As hard phase of refractory metal, the tungsten steel is used with transition metal (Co, etc.) as the binder phase. The super-hard material prepared by powder metallurgy technology is cemented carbide.

Cemented carbide has the advantages of high strength, high hardness, wear resistance, corrosion resistance, high temperature resistance and small coefficient of linear expansion. It is one of the excellent tool materials, widely used in many industrial production and processing operations. Especially for the use of precision mold equipment, such as the tungsten carbide is processed into tungsten steel pin used in the AR8 anti-vibration rotor core stamping mold.

Material performance is the basic use requirement, and long-lasting life is the efficiency guarantee for industrial mass production.

Technical Parameters

Good physical stability is the basic requirement for tungsten carbide products. It can be used in special conditions for its excellent performance of wear resistance, high temperature resistance and corrosion resistance. This is how the excellent performance tools can directly improve production efficiency.

We can provide punching pins and sleeves used for precision mold parts, we can also produce tungsten steel inner and outer rotor pin, rotor forming pin, rotor metering pins, etc. according to the core stamping mold requirements of the customers. According to the actual operation requirements and customer's specific drawing as the precision tolerance standard, we provide non-standard forming of tungsten carbide.

Physical Parameters of Conventional Tungsten Carbide

• Grain size (um): 0.8 ~ 2.0

• Cobalt content (Co%): 6 ~ 10

• Density (g/cm³): 14.45

• Hardness (HRA): 88 ~ 92

• Bending strength (Mpa): 3200 ~ 3800

• Young's modulus (Gpa): 570

• Compressive strength (Mpa): 4700

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!