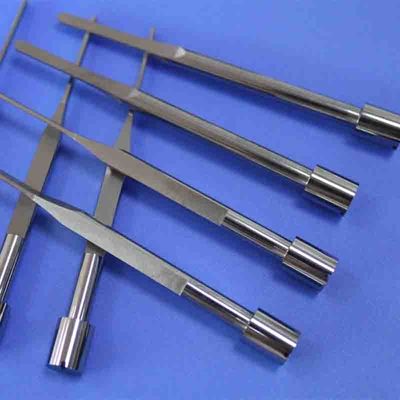

OEM Steel Slag Wear Part Tungsten Carbide Punch Mold for Stator Iron Core

Punches and dies used in conjunction with stamping molds for the production of stator iron cores.

Hard alloy punches, with their excellent material properties, serve as core components in stamping molds for continuous cutting, punching, and breaking operations. These punches are installed on stamping molds to induce separation or plastic deformation in the processed material, resulting in the desired finished or semi-finished product. Stamping molds, in cold stamping processes, shape materials into components. Stamping is a pressure processing method commonly used in industrial production, performed at room temperature by applying pressure to materials using molds installed on a press.

Stamping molds are indispensable in stamping production and are considered technologically intensive products. The quality, production efficiency, and production costs of stamped parts are directly related to the precision and quality of mold design and mold components.

Product Advantages

Our company specializes in producing and manufacturing hard alloy insert punch molds and punch pins for precision mold customers. These components are used with electronic ceramic injection molds where precision requirements are extremely high, and perfect product consistency is the primary standard.

The tungsten carbide punching pins equipped in electronic ceramic precision molds are used in large quantities, with each insert pin required to maintain excellent consistency. This demands strict control over every processing procedure during finishing operations.

Our company produces hard alloy insert pins according to precision mold manufacturer requirements, guaranteeing product consistency with tolerance requirements of +0.002. The finish of the punch needles is required to be 0.2, meeting the highest application standards for electronic ceramic injection molds.

| National high-tech enterprise certification |

| Processing High tolerance accuracy ±0.001mm |

| Wear-resistant, heat-resistant, and anti-corrosion |

Company Profile

Zhuzhou Sanxin Cemented Carbide Manufacturing Co., Ltd is engaged in R&D of cemented carbide raw material, processing, selling and aftermarket services.

Sanxin dedicates itself to inheriting tungsten carbide OEM services and improvement solutions, with a specialized technical team as a solid foundation and obvious superiority to manufacture high-quality tungsten carbide products.

- Established in 2003

- Two main factories built in 2007

- Passed ISO 9001:2015 in 2017

- High-tech Enterprise Identified in 2017

- Obtained foreign trading license 2017

- Confirmed as supplier of CLEP in 2021

- Owned more than 20 patent certificates

We always carry out "quality and customer first", "Samples available", "punctual delivery", "mutual benefit", "focus on innovation", "service creates value" business policies in the market. Sanxin delivers carbide value.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!